The failed samples account for more than 80 per cent of the Hong Kong market, raising serious safety concerns and questions for regulators

More samples of fire-resistant electrical cables used in Hong Kong buildings have failed fire safety tests, following FactWire’s revelation last April that samples from a public housing estate also fell short of international standards.

The failed samples cover five major brands, which dominate more than 80 per cent of the Hong Kong market, raising serious safety concerns and questions for regulators.

The wires were originally connected to fire service installations such as fire alarms, emergency lighting and ventilation before they were taken down for testing, meaning that they could all malfunction in a fire and potentially result in catastrophic consequences.

Industry sources, who were stunned by the results, have urged the government to conduct sampling tests on fire-resistant cables, instead of just relying certification documents submitted by contractors.

‘Fire-resistant cables are a lifeline in a fire,’ said an electrical supervisor, who has worked in the construction industry for more than 30 years and does not wish to be named.

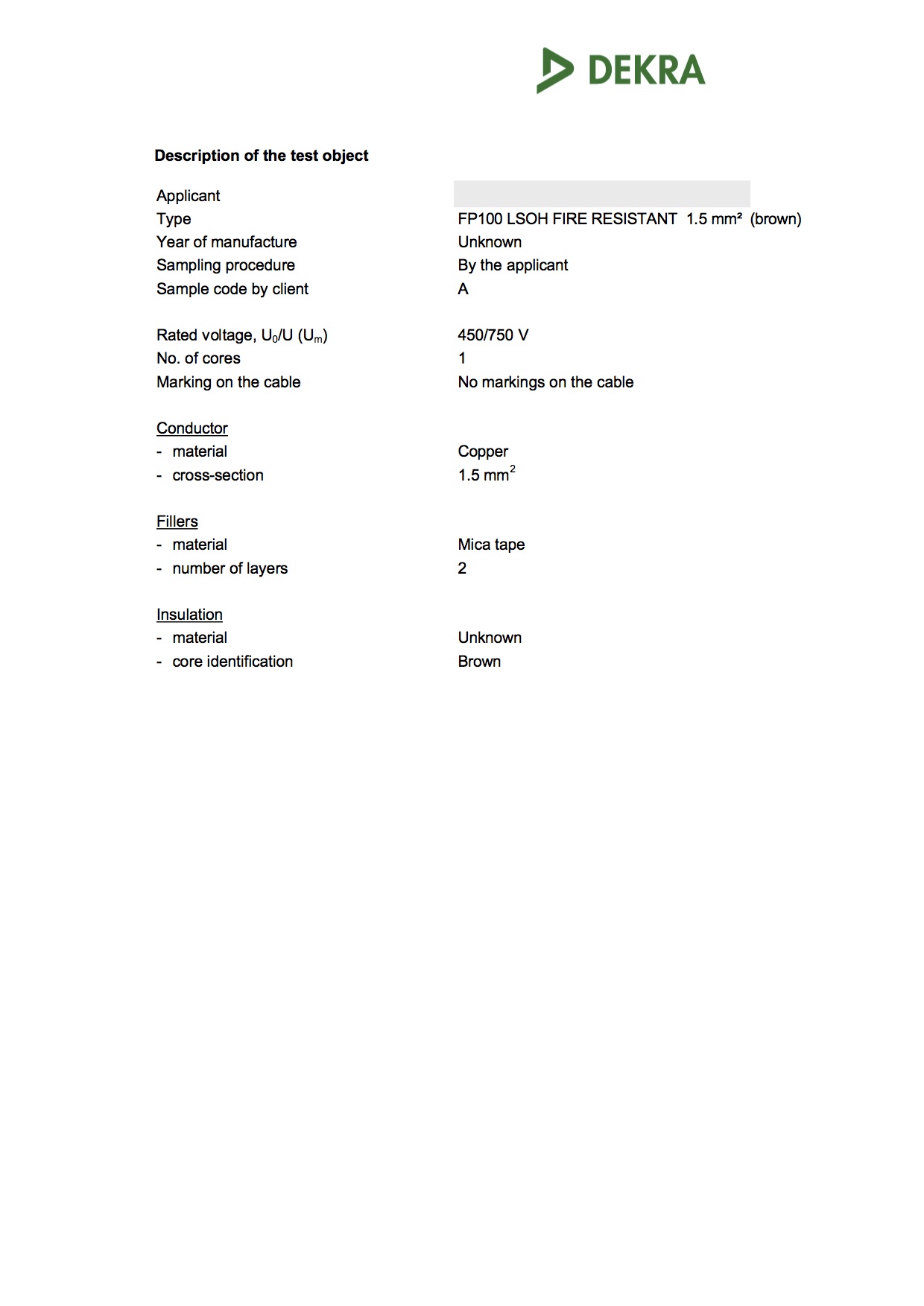

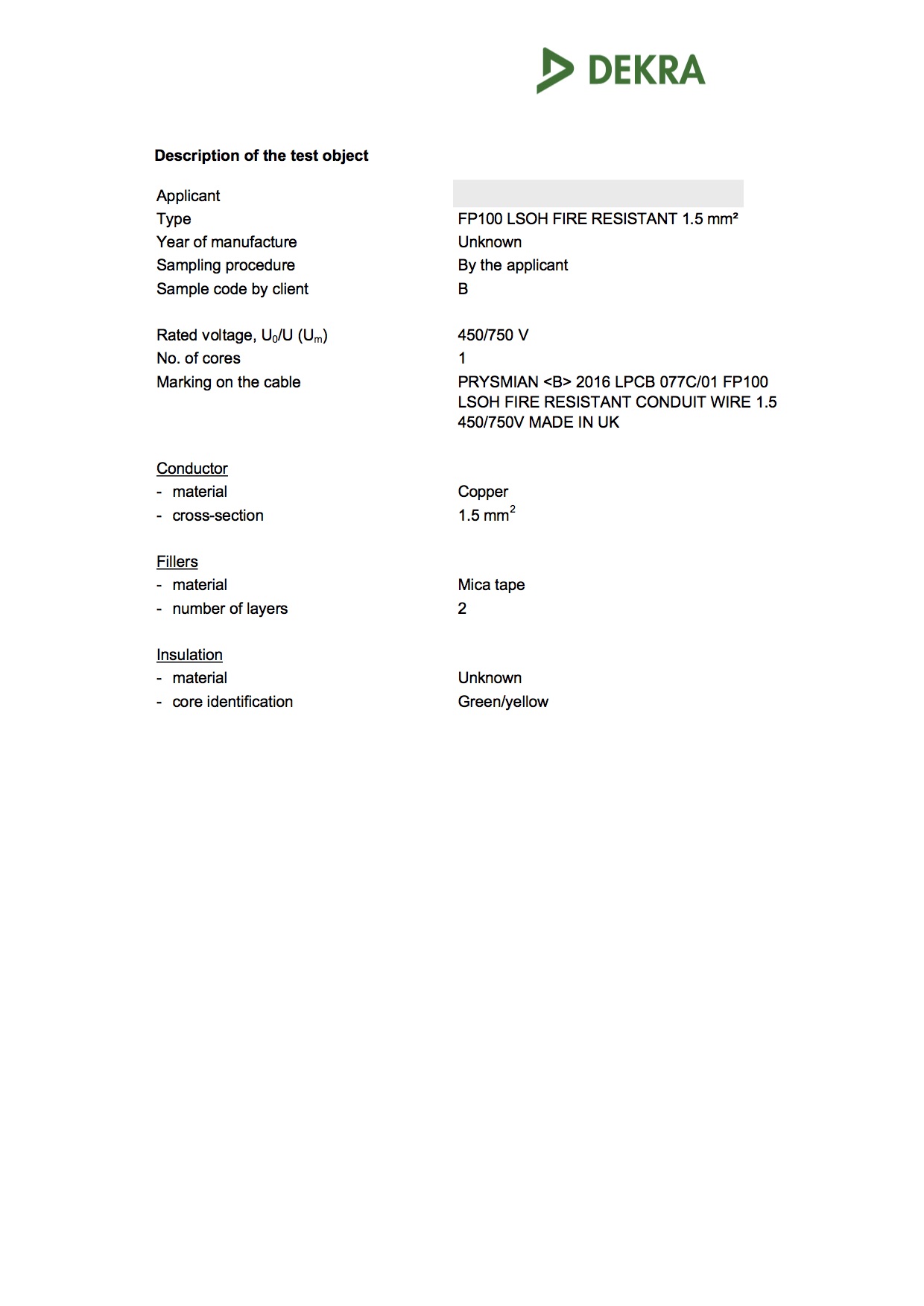

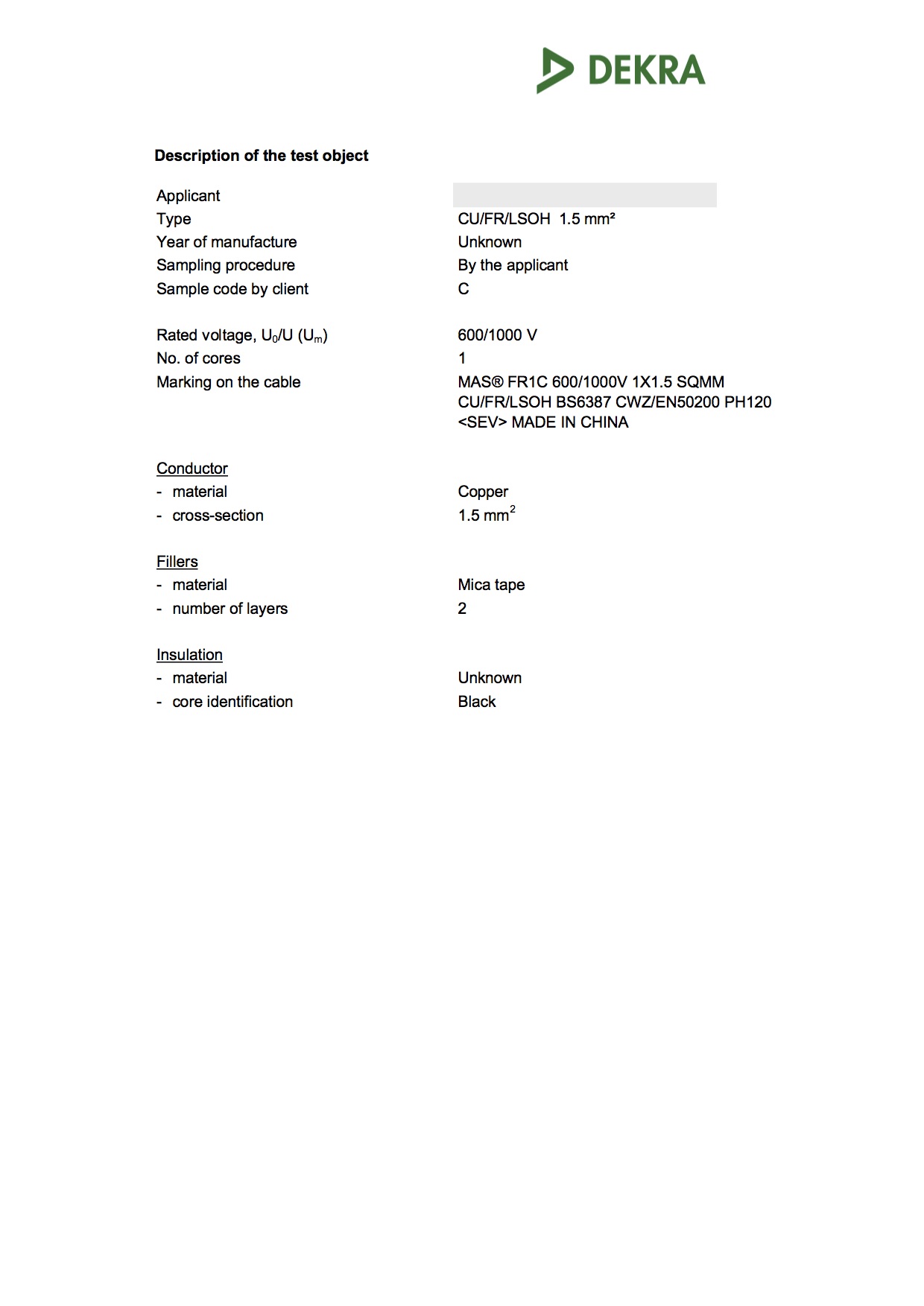

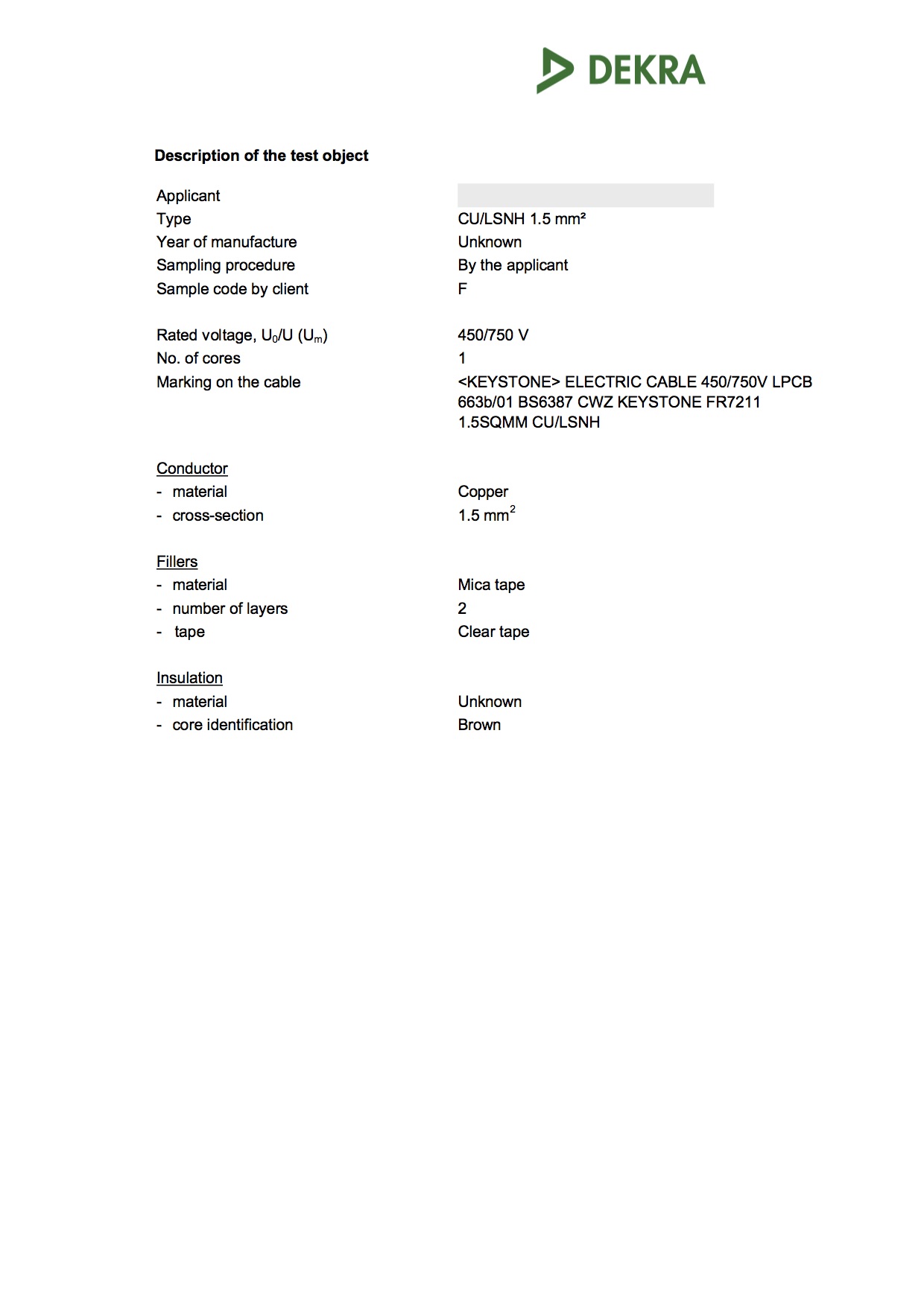

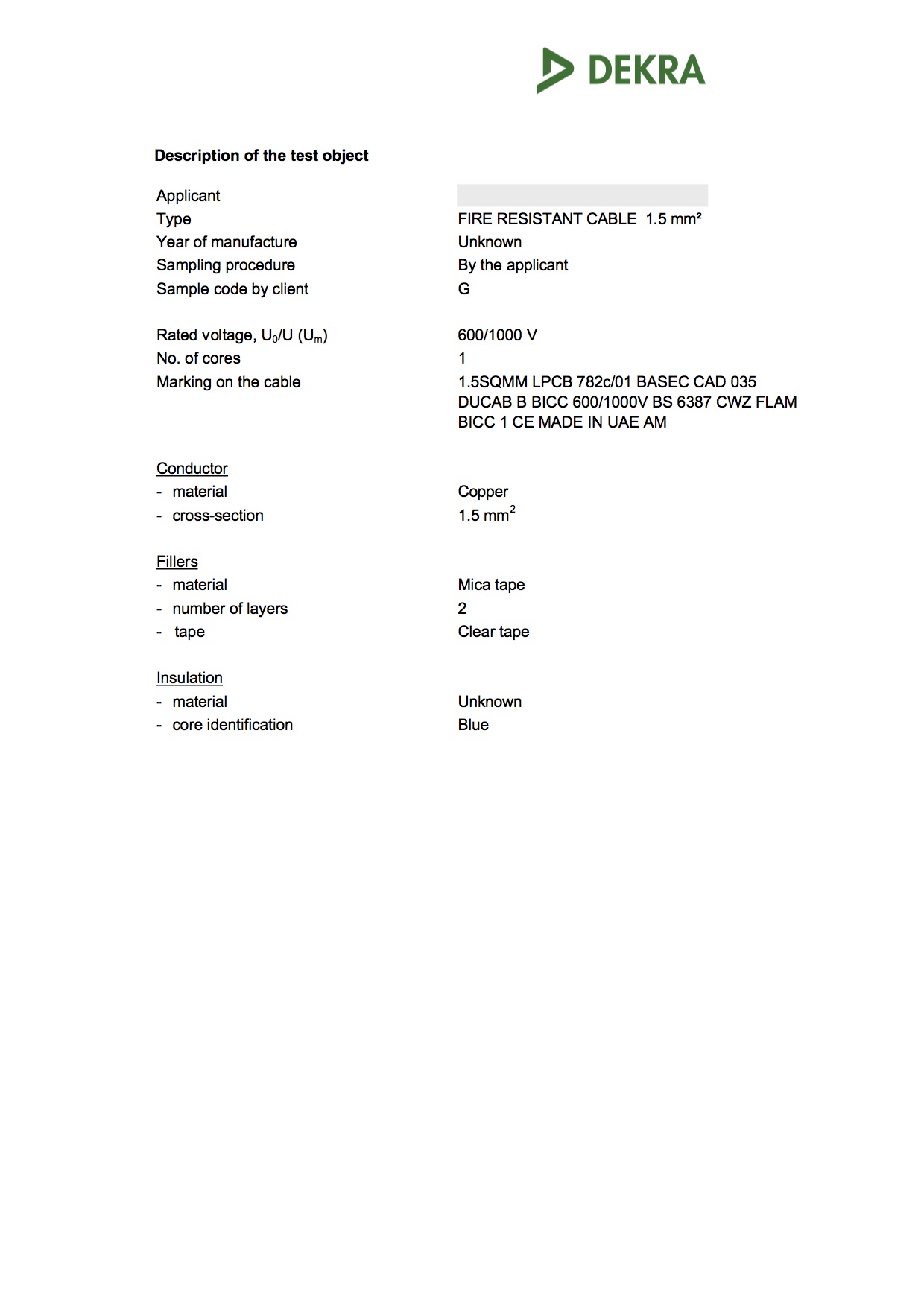

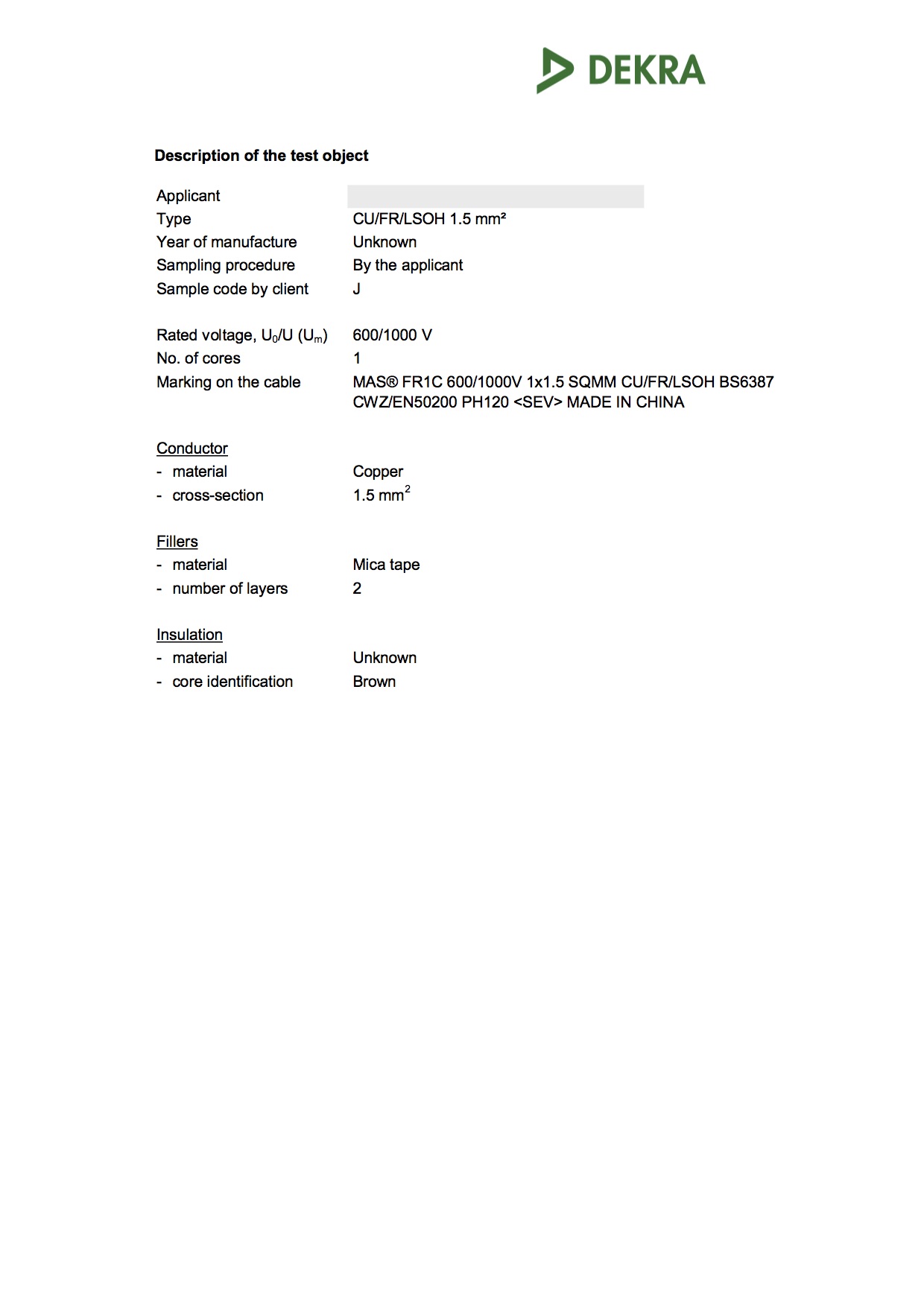

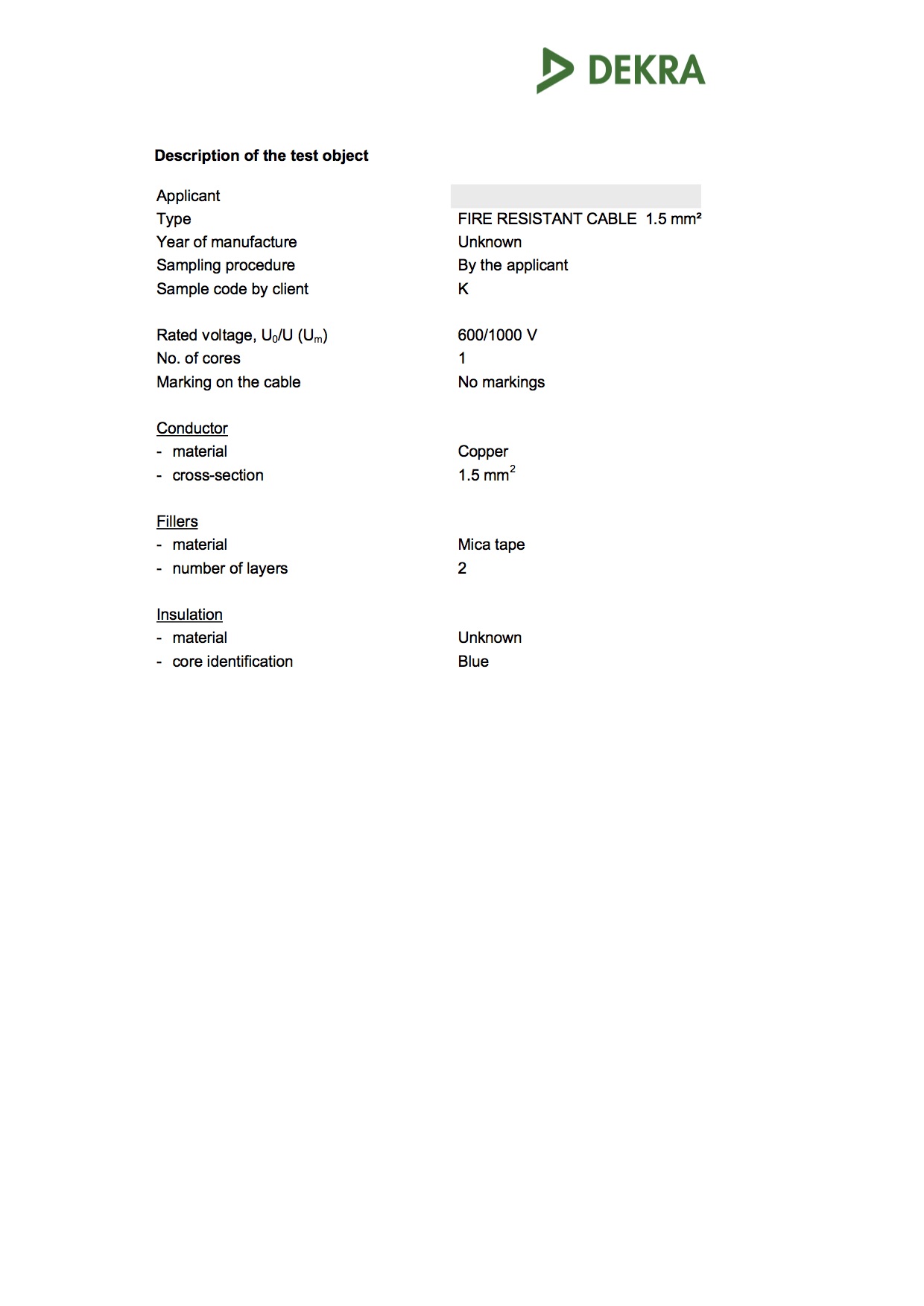

A fire-resistant cable is different to a normal cable in that, beneath the plastic sheath, the copper wires in the former are wrapped by layers of mica tapes which extend the durability of the cable under extreme heat.

It is impossible to evaluate the quality of the mica tapes inside a cable with the naked eye or conventional functioning tests, he said.

The 12 samples FactWire obtained in the past six months include six from Tuen Mun Hospital, three from the residence halls of City University of Hong Kong (CityU), two from the Choi Tak Estate in Ngau Tau Kok and one from the construction site of Hong Kong Children’s Hospital in Kowloon Bay.

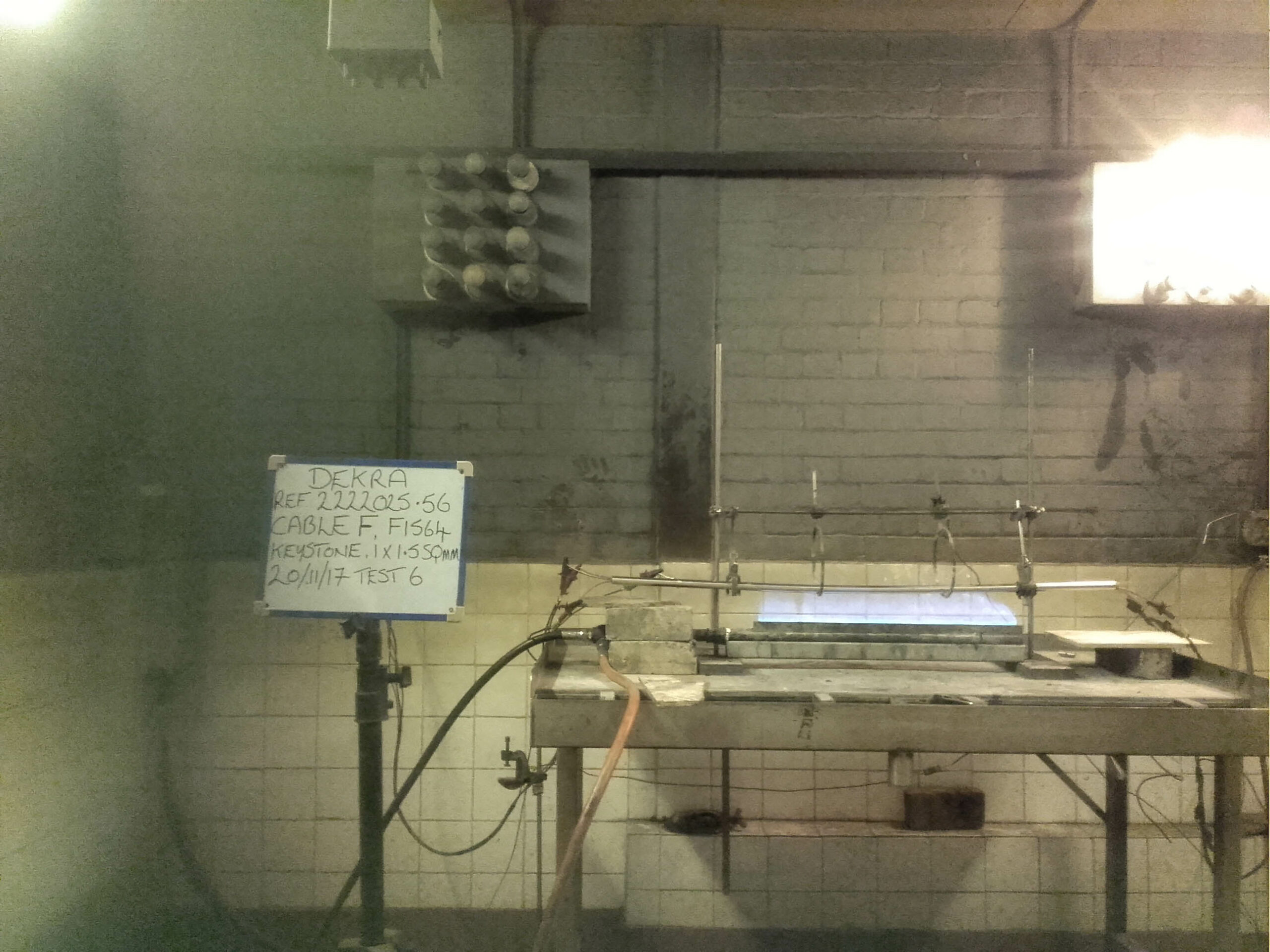

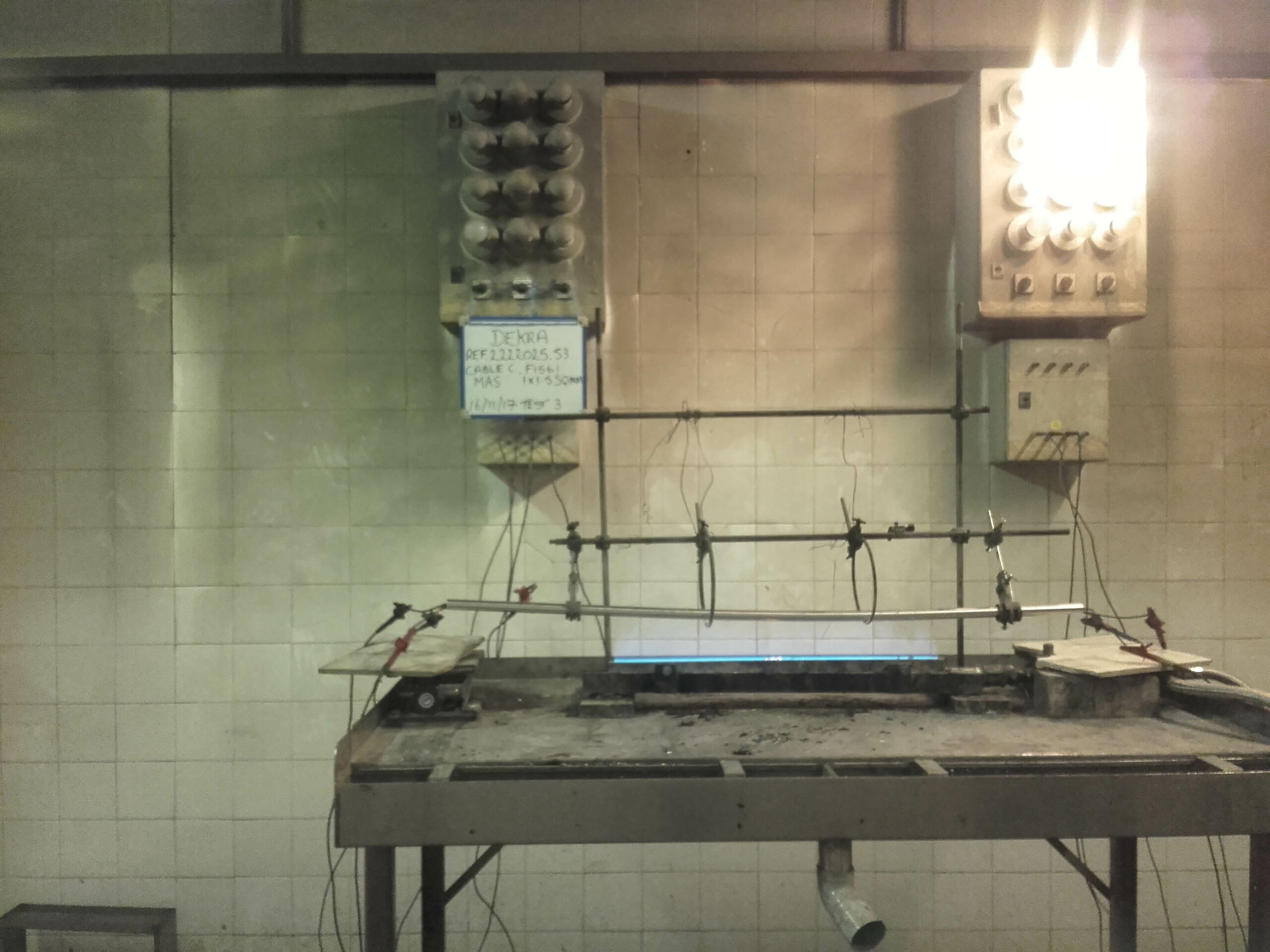

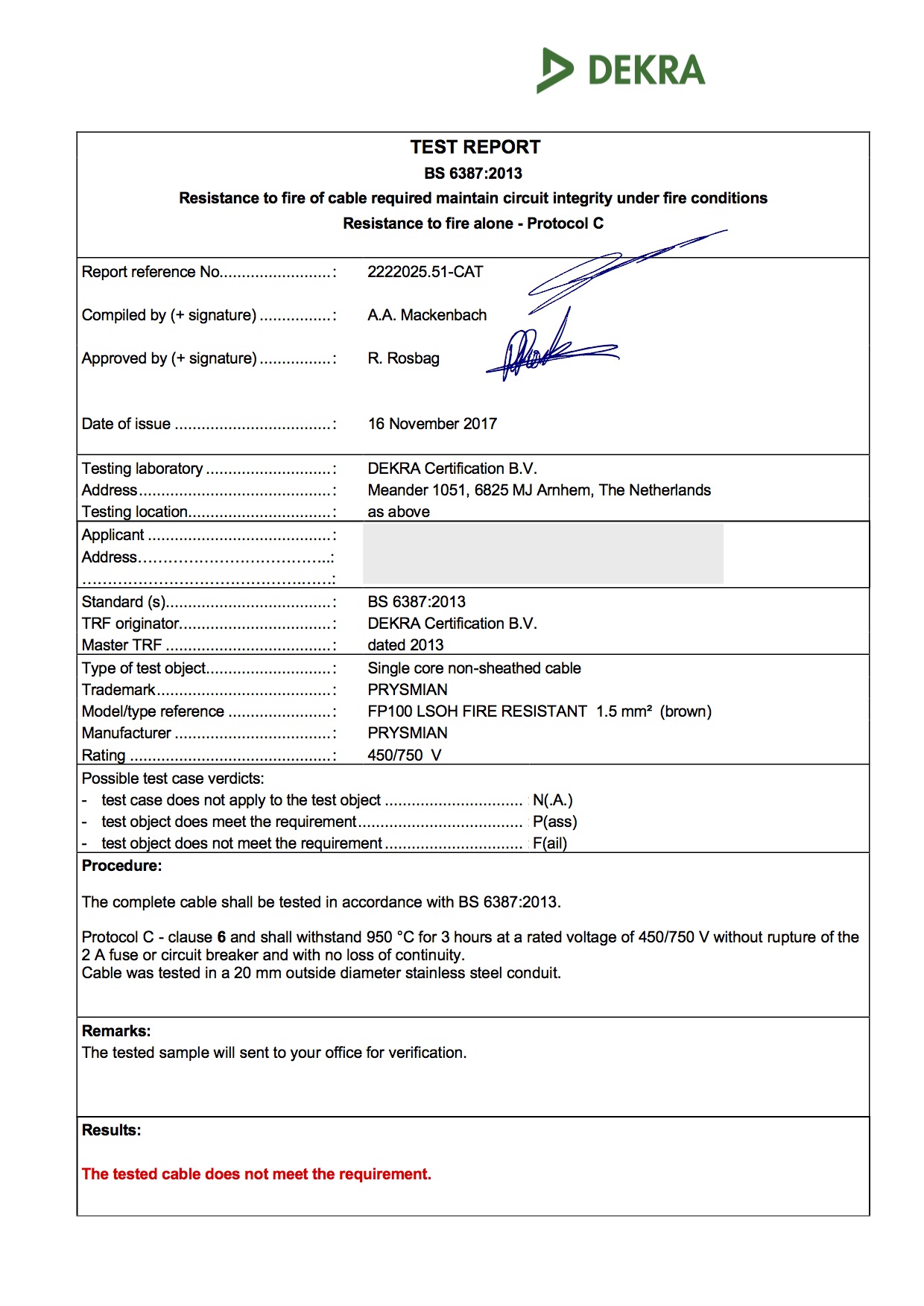

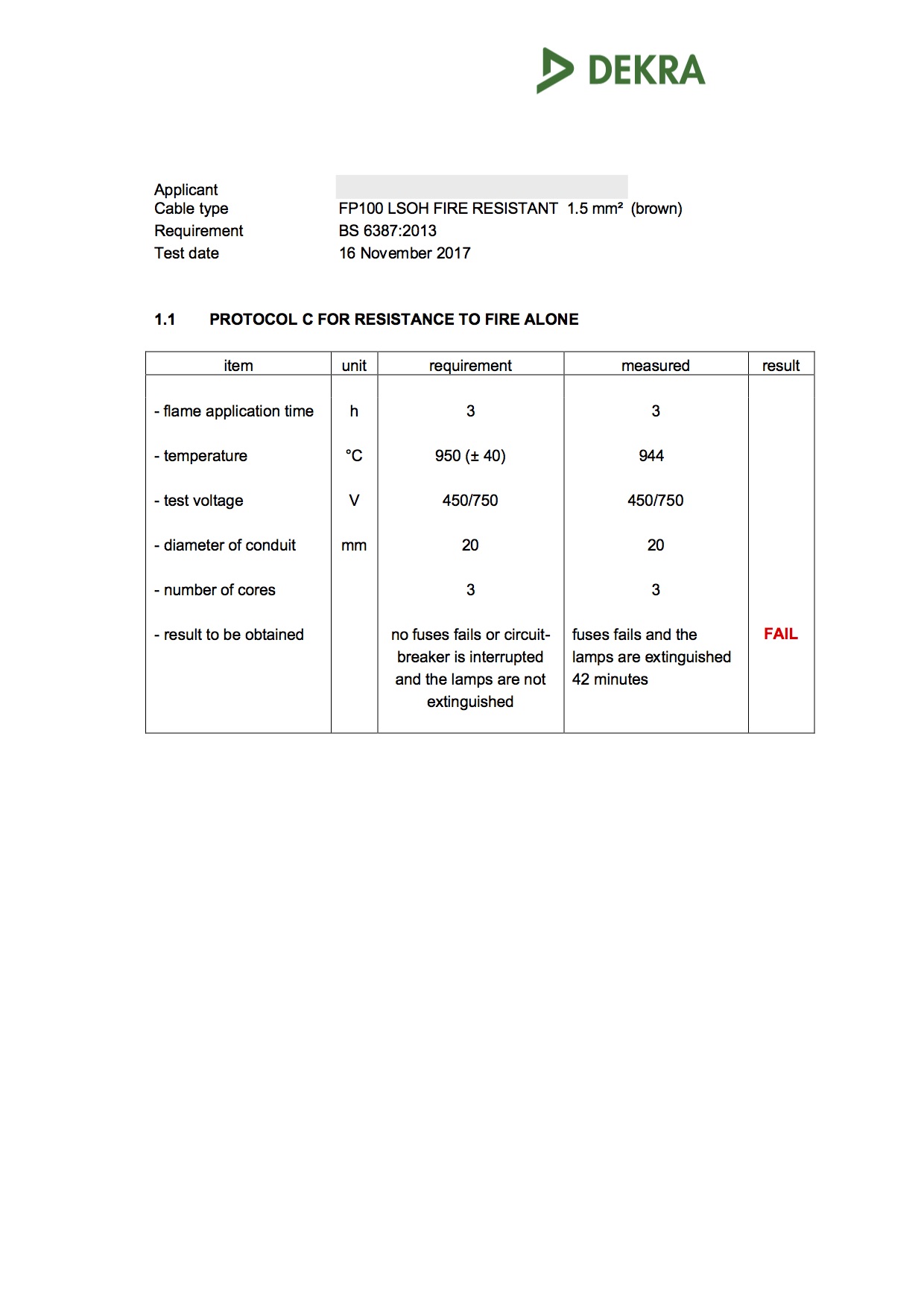

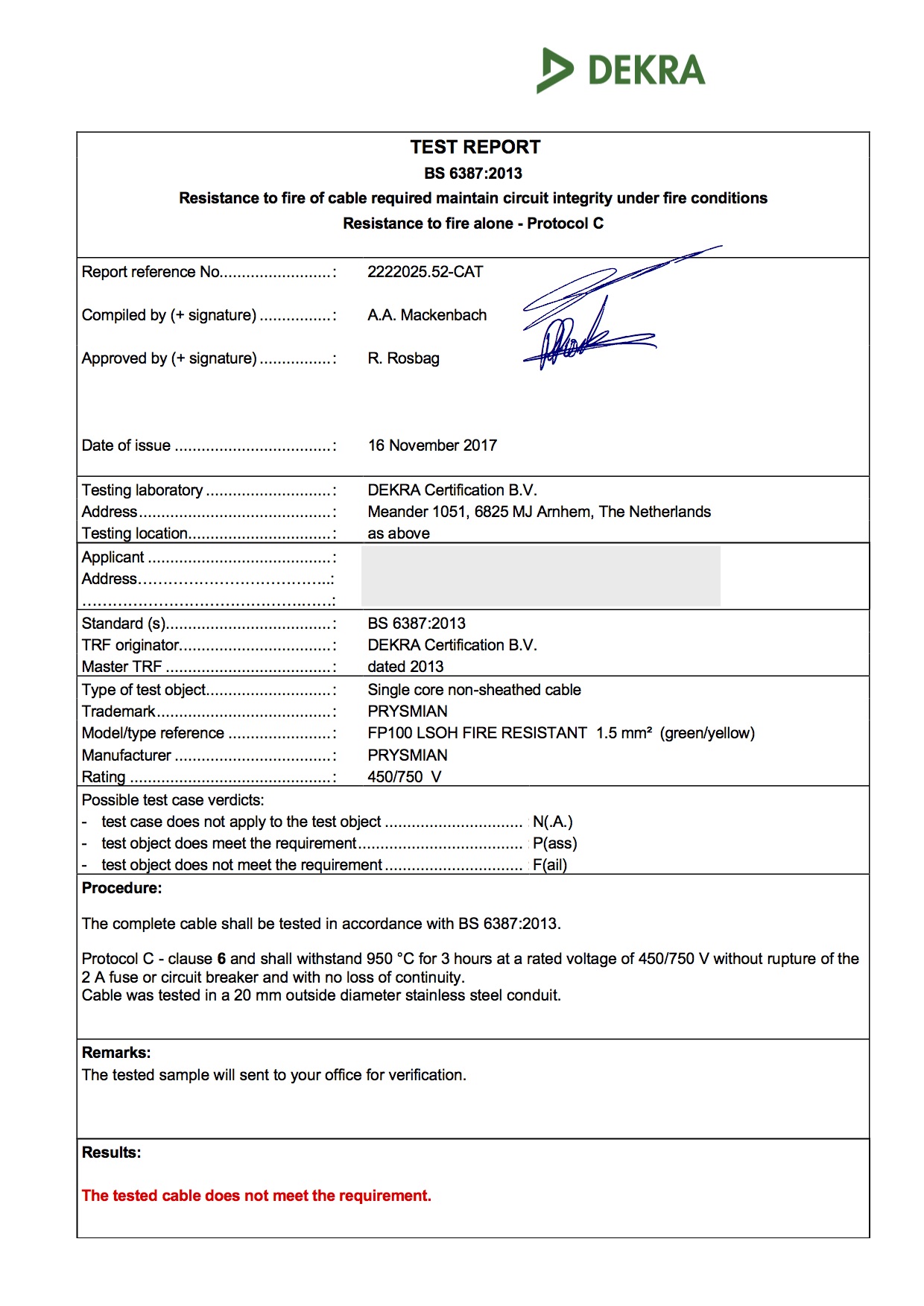

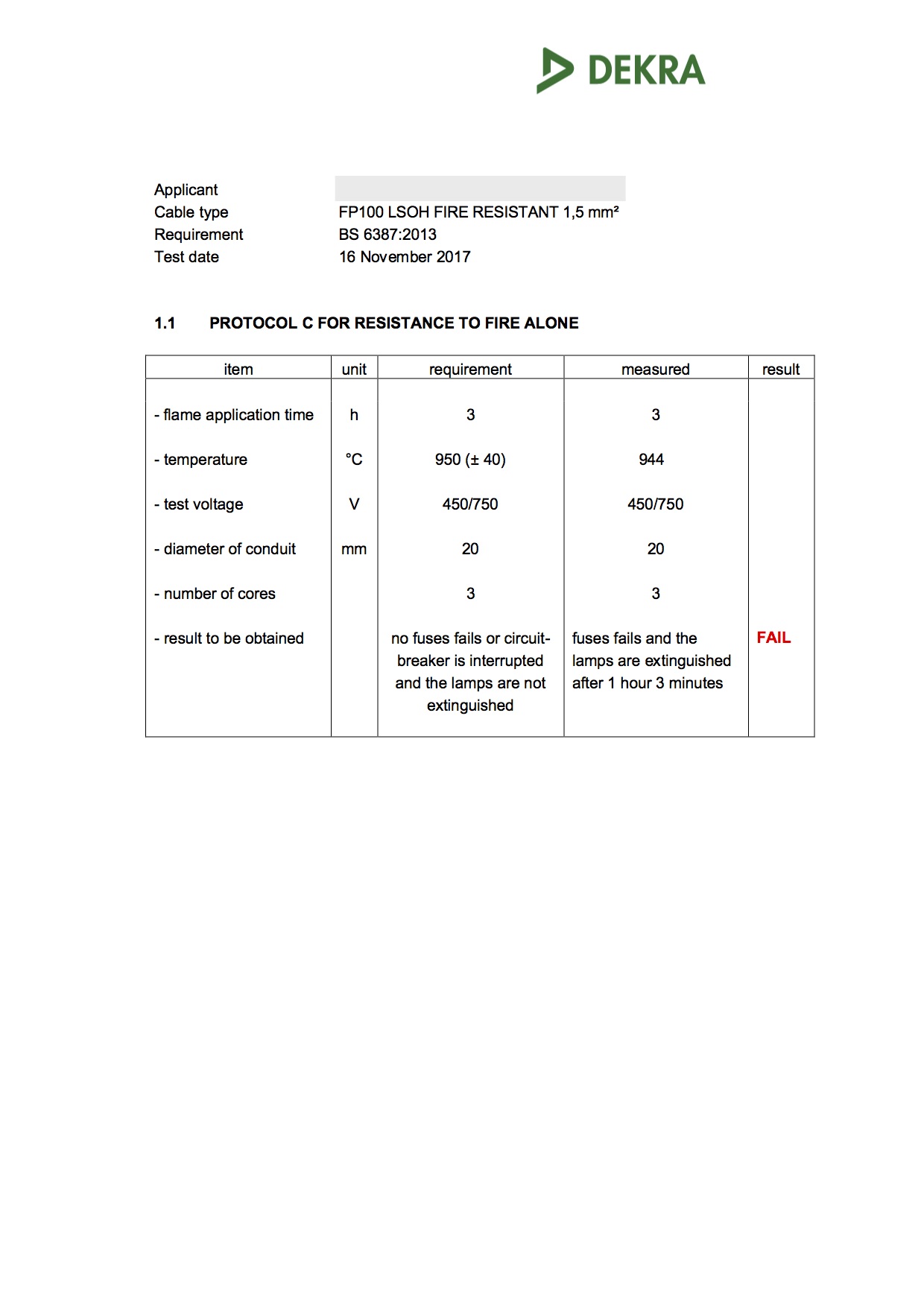

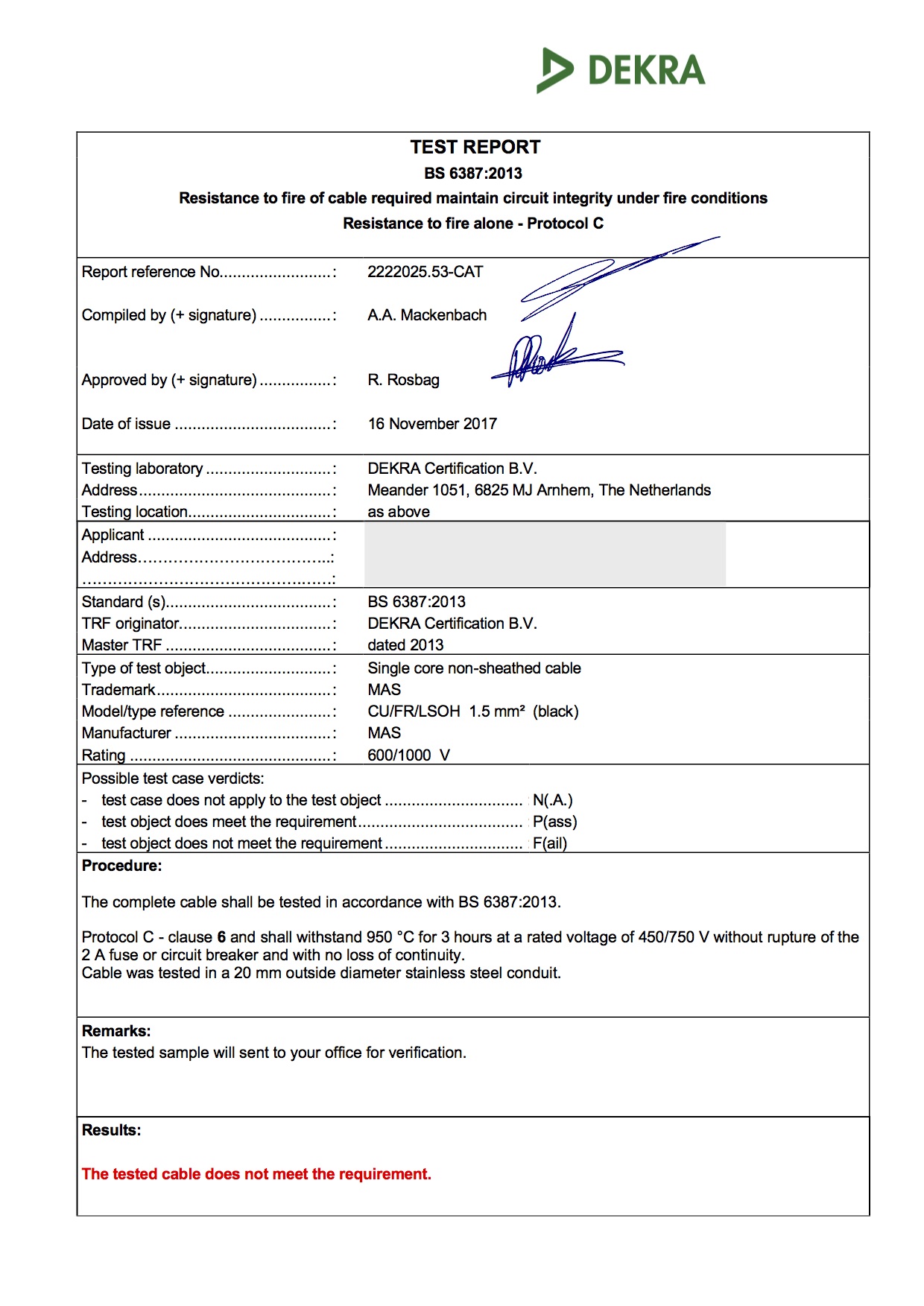

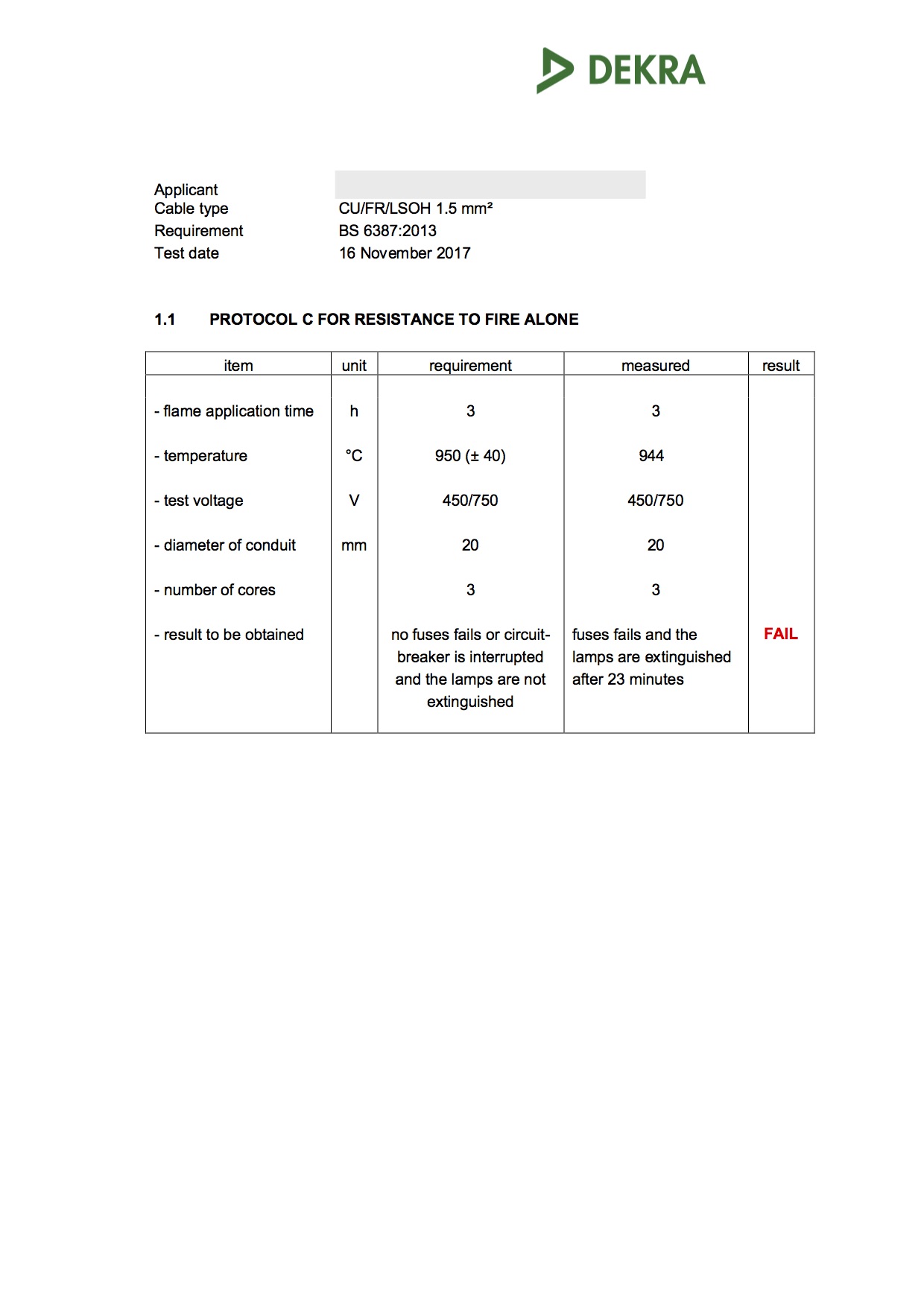

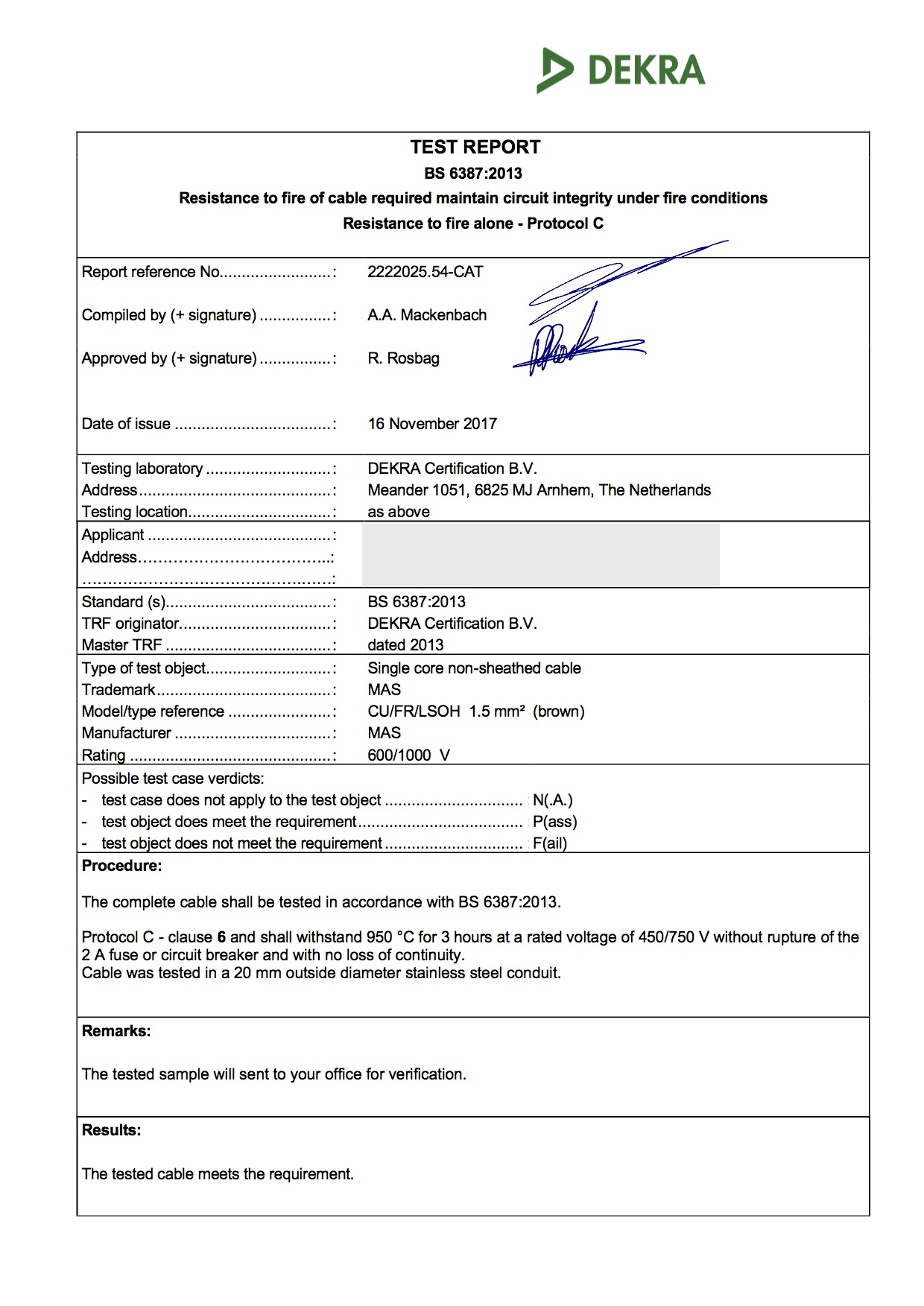

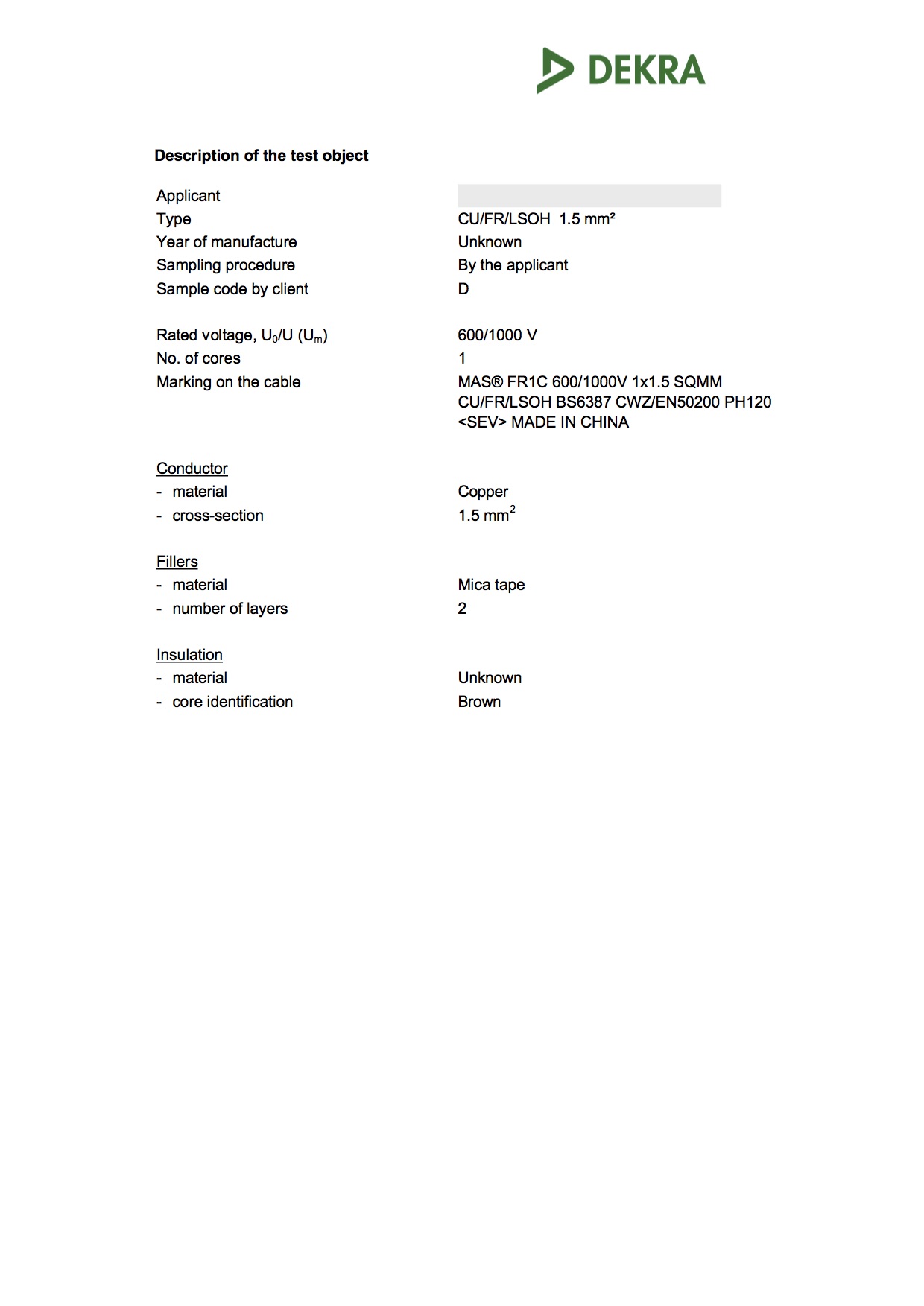

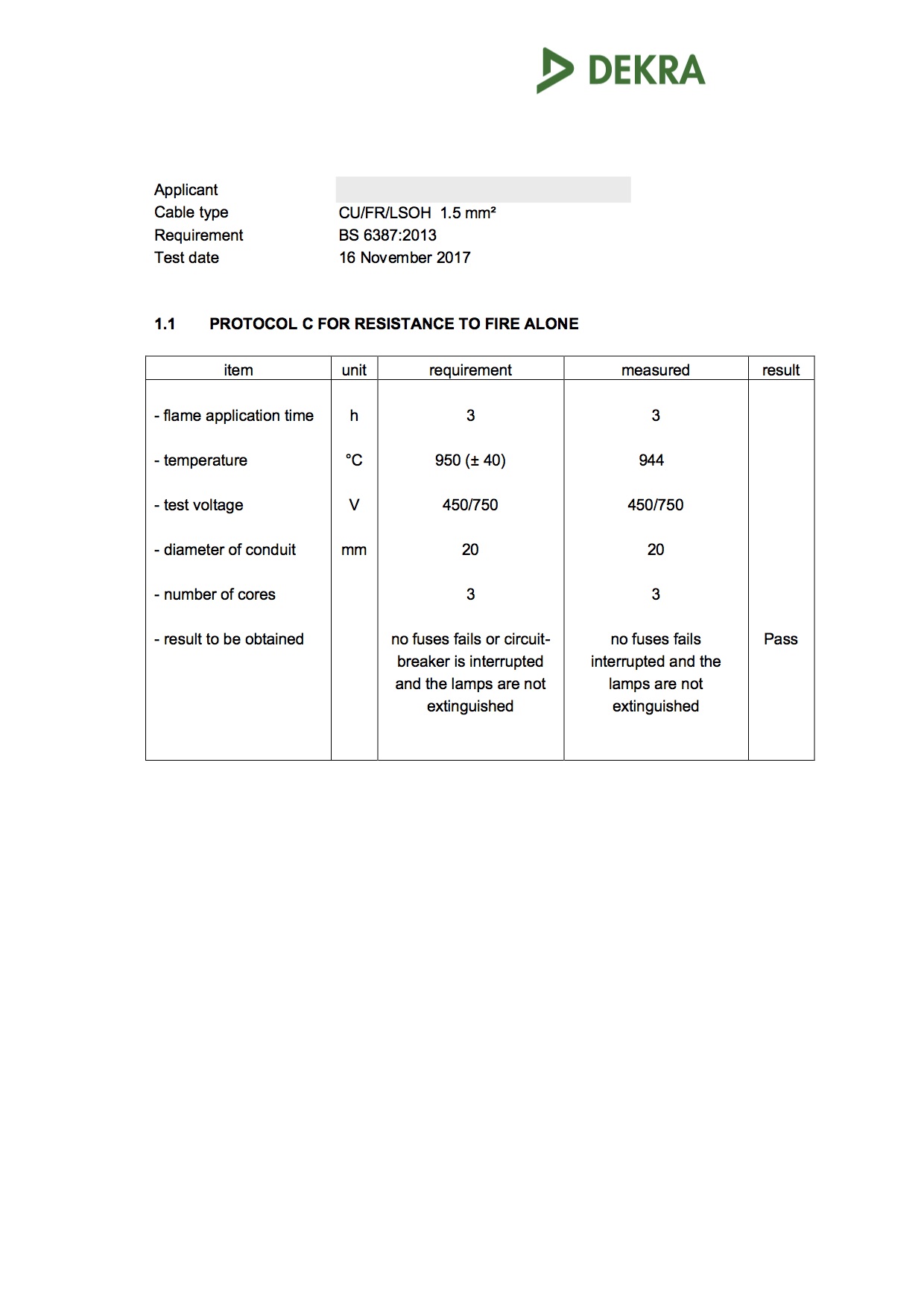

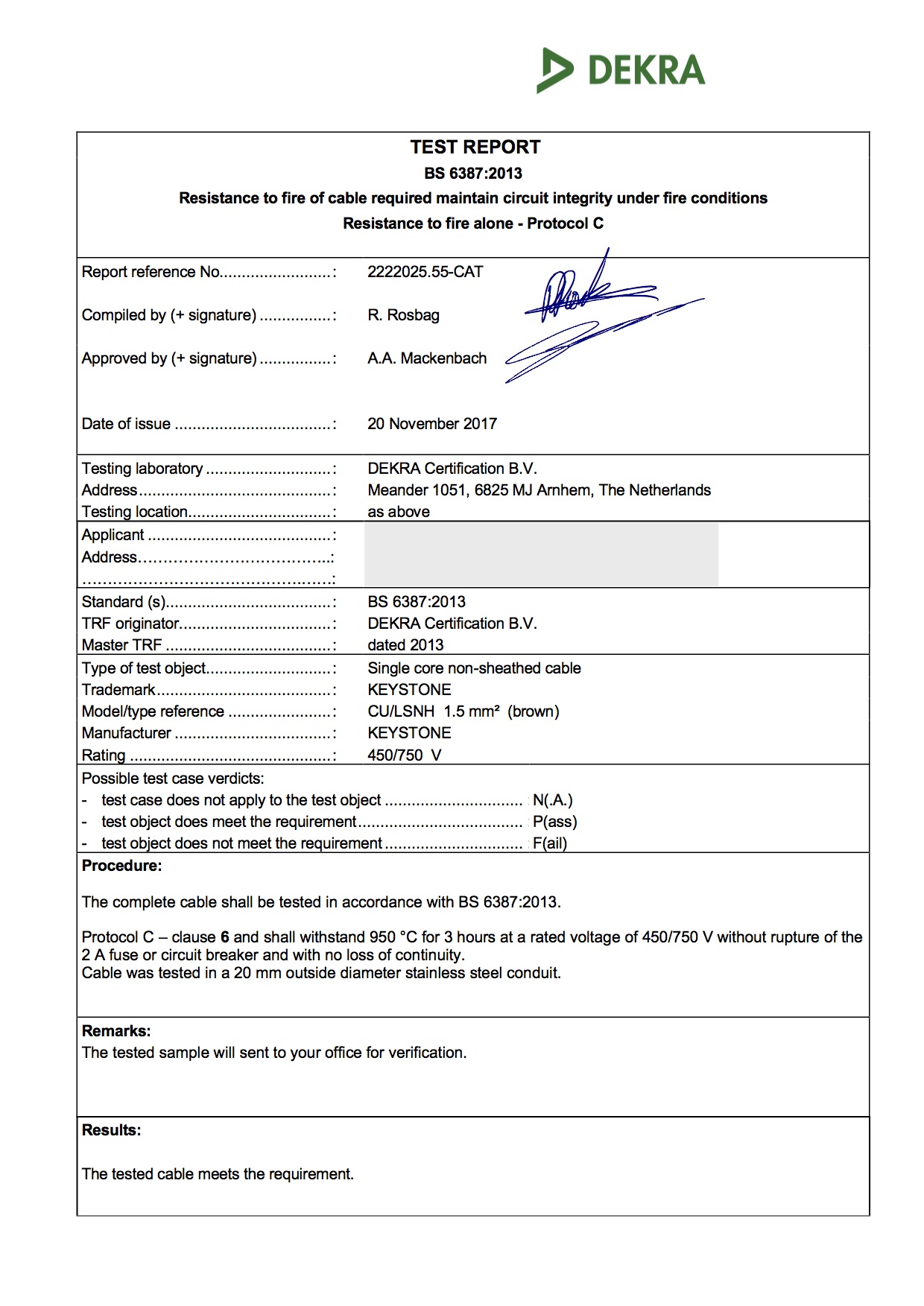

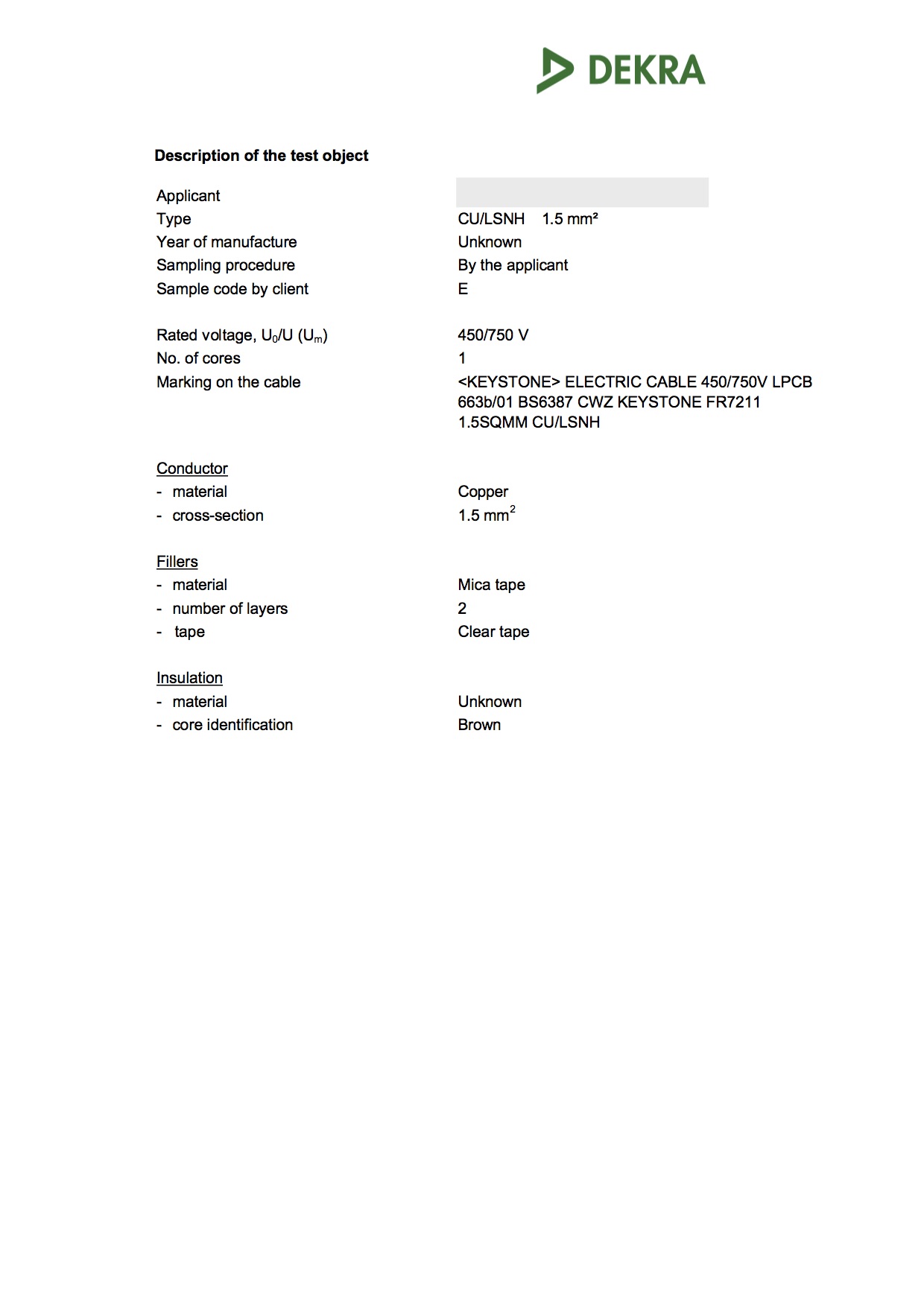

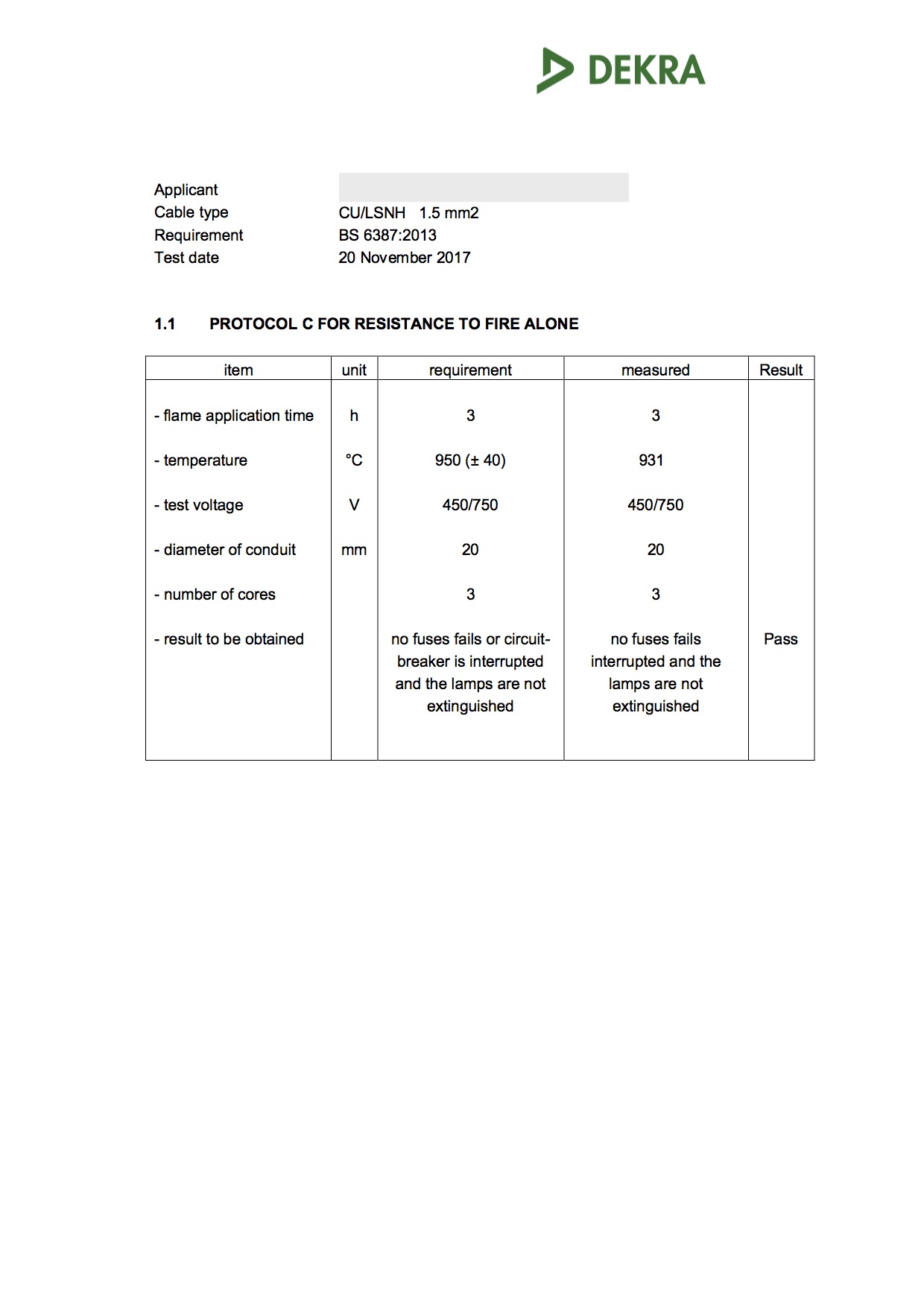

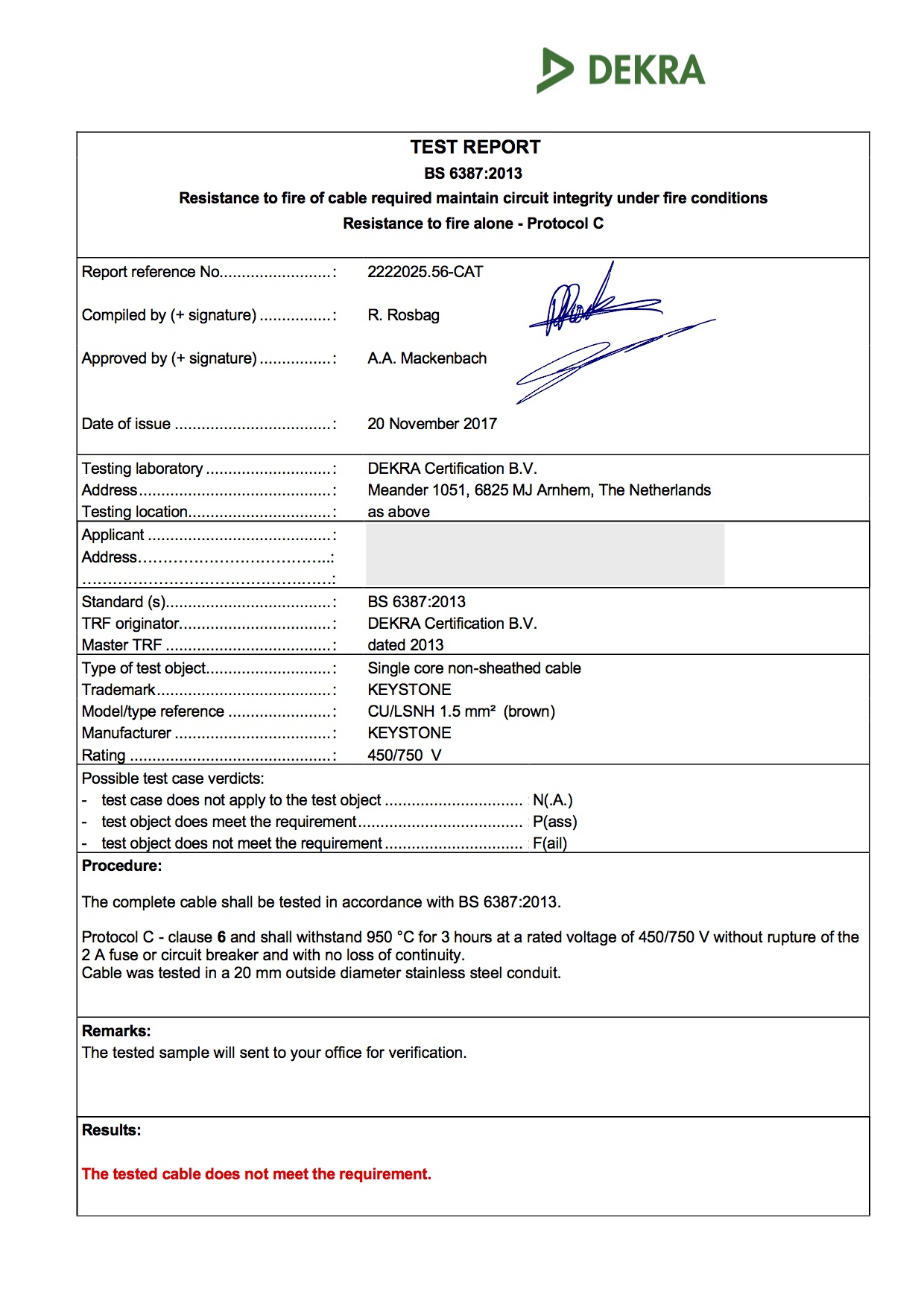

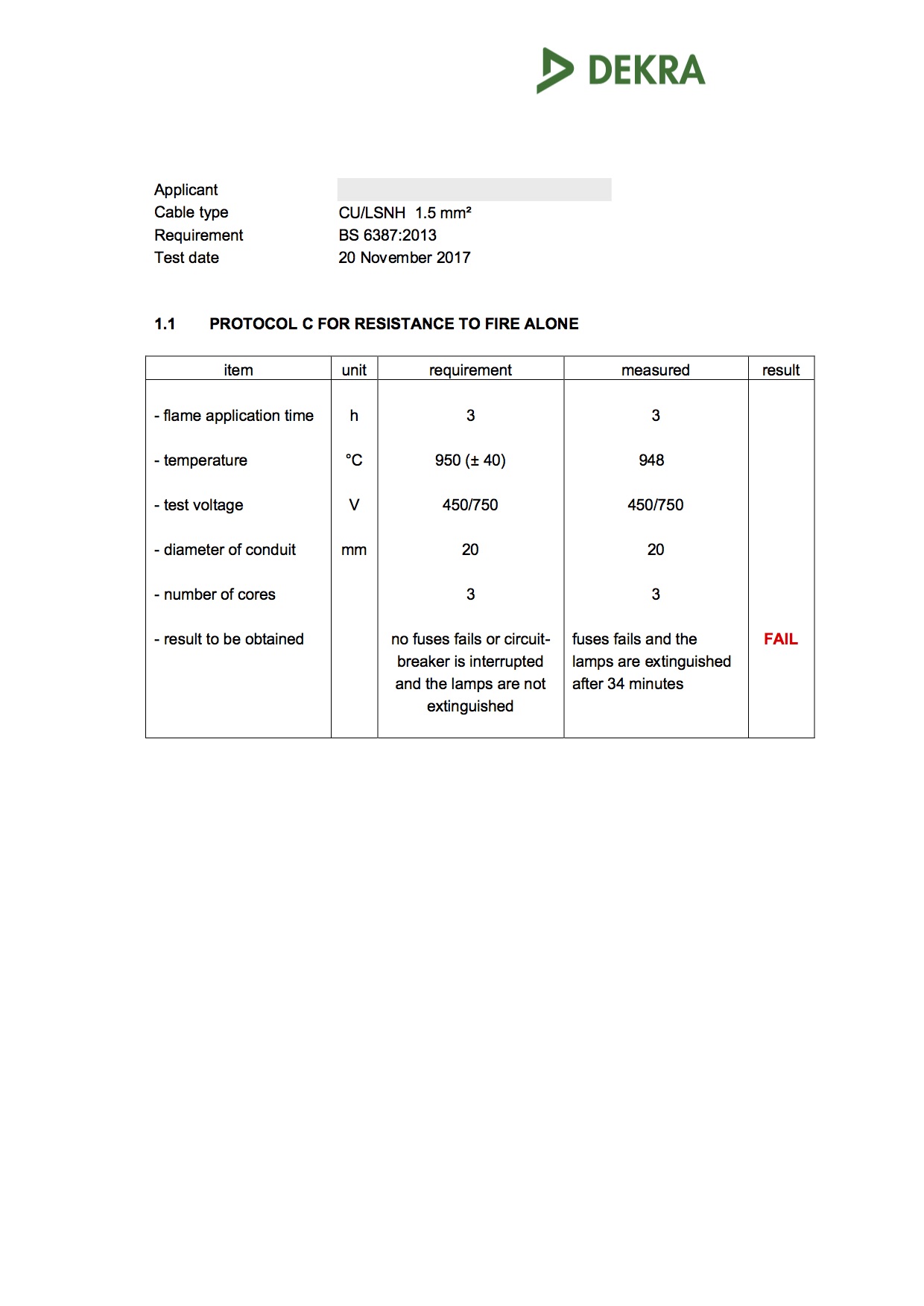

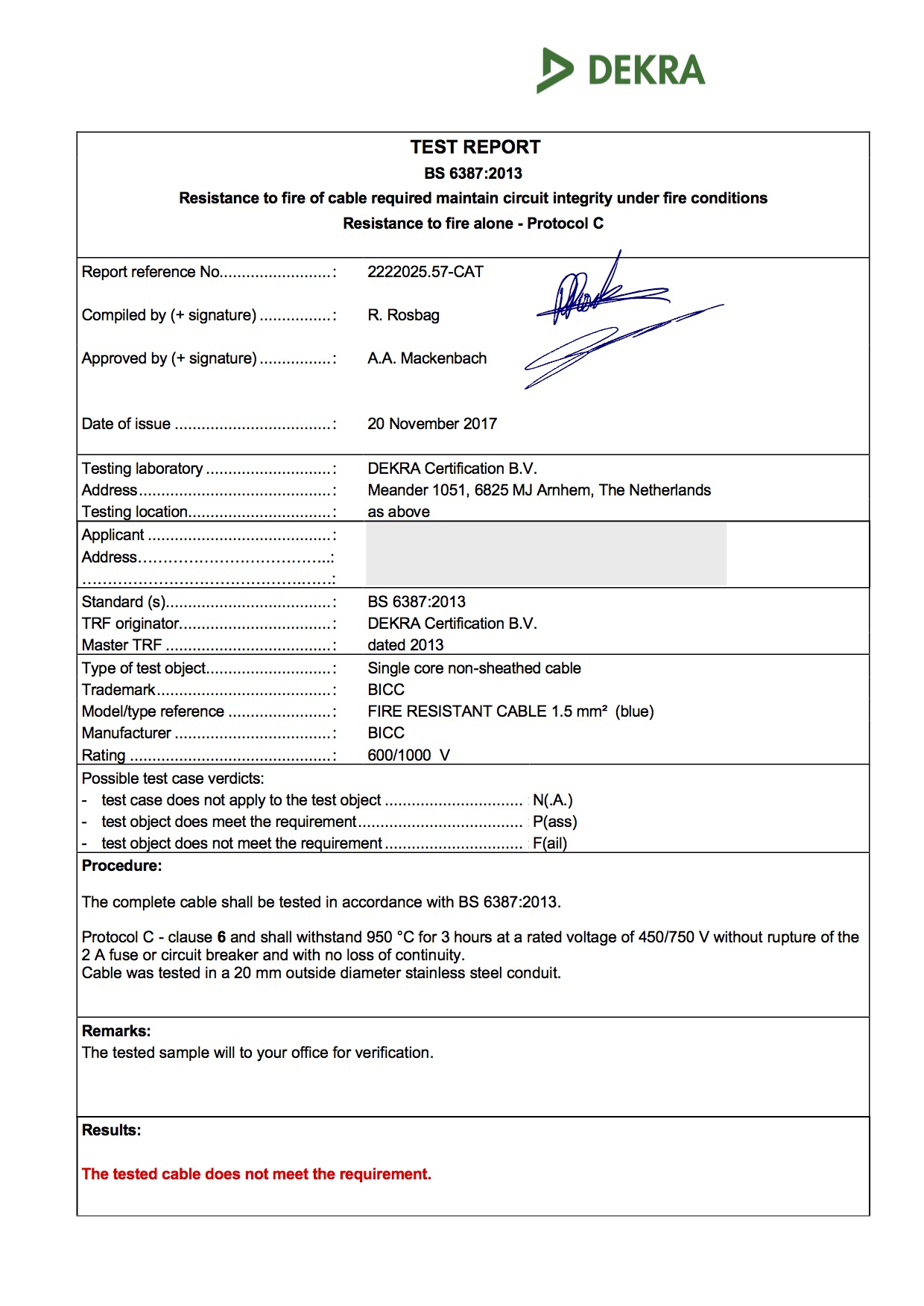

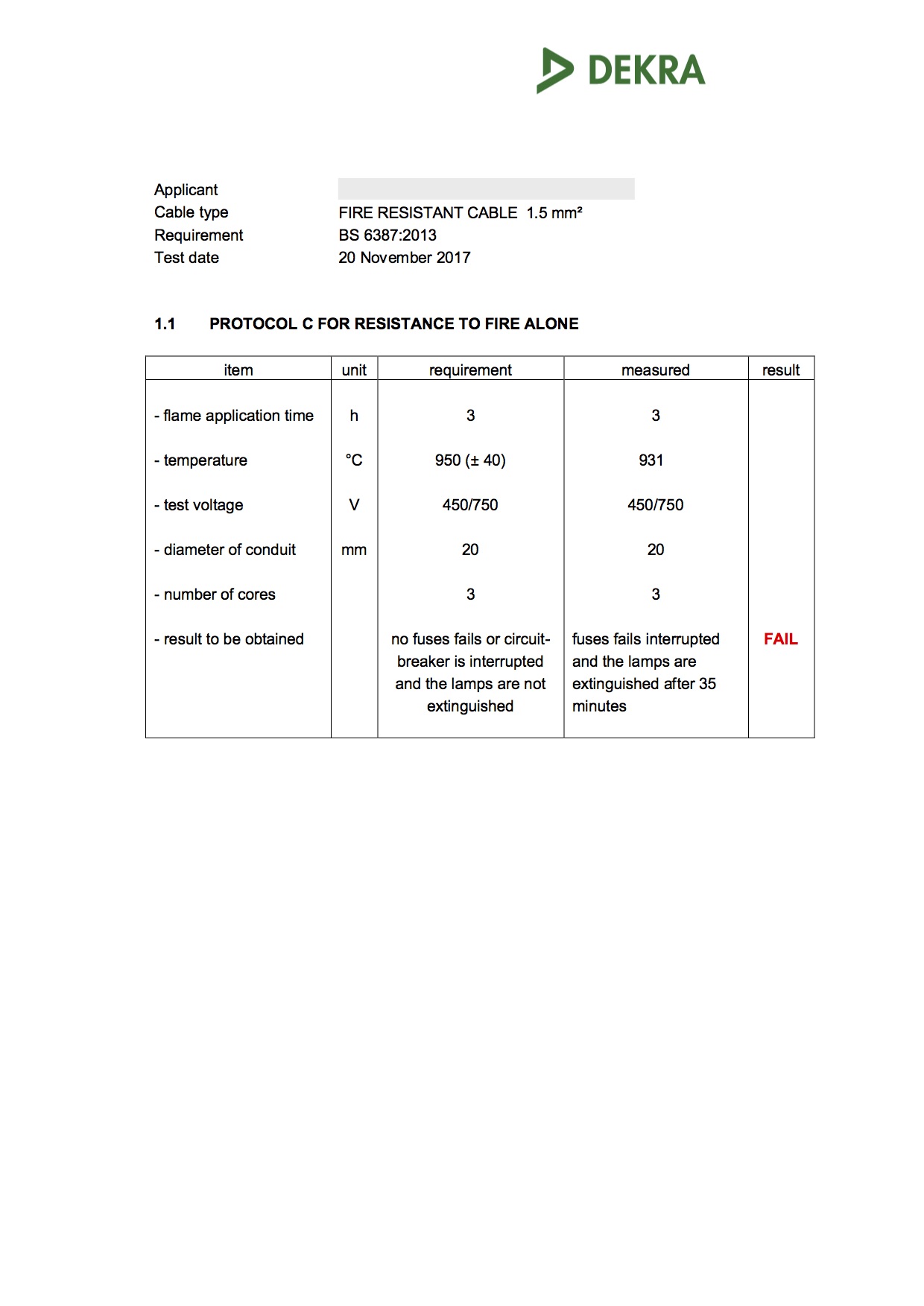

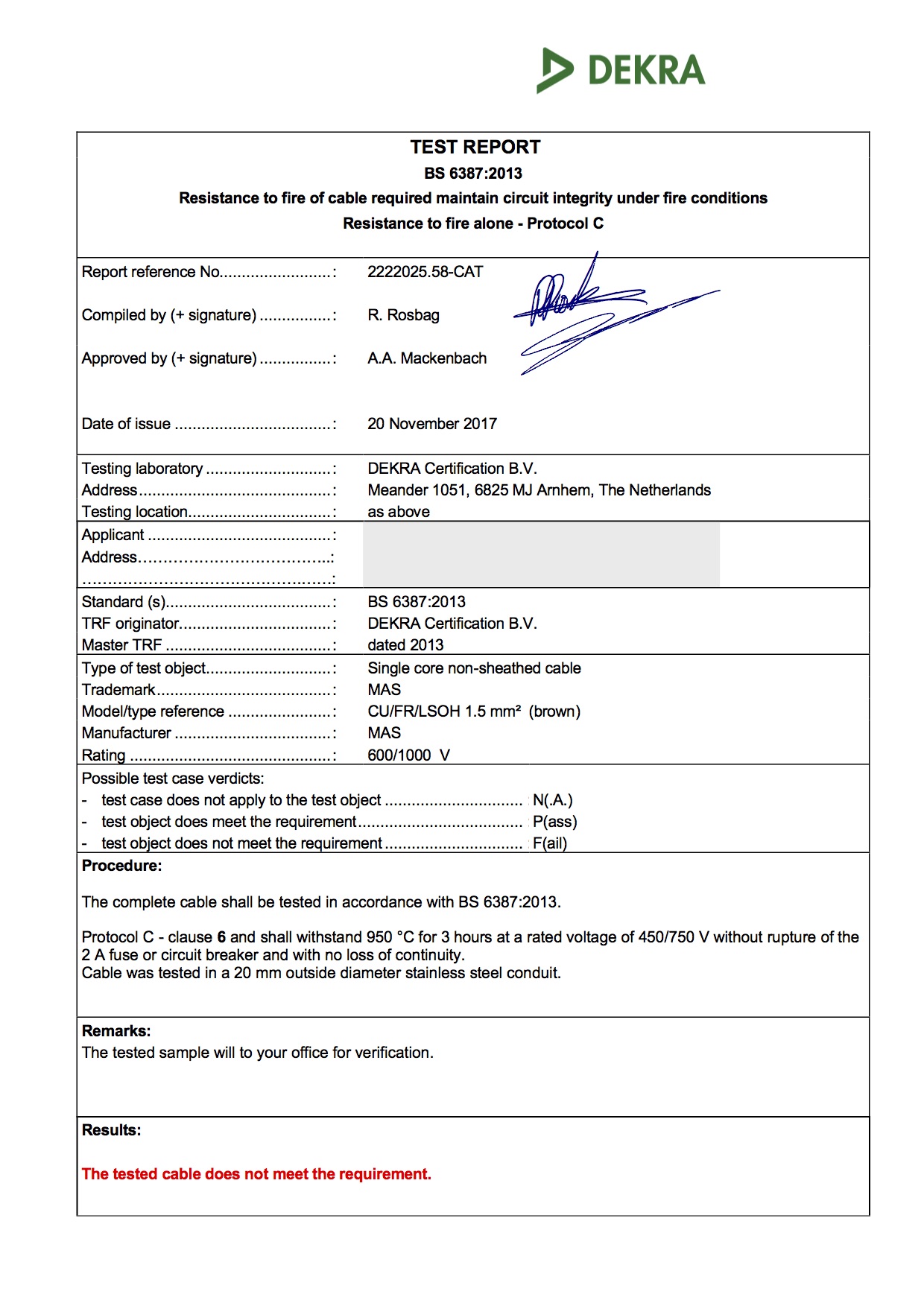

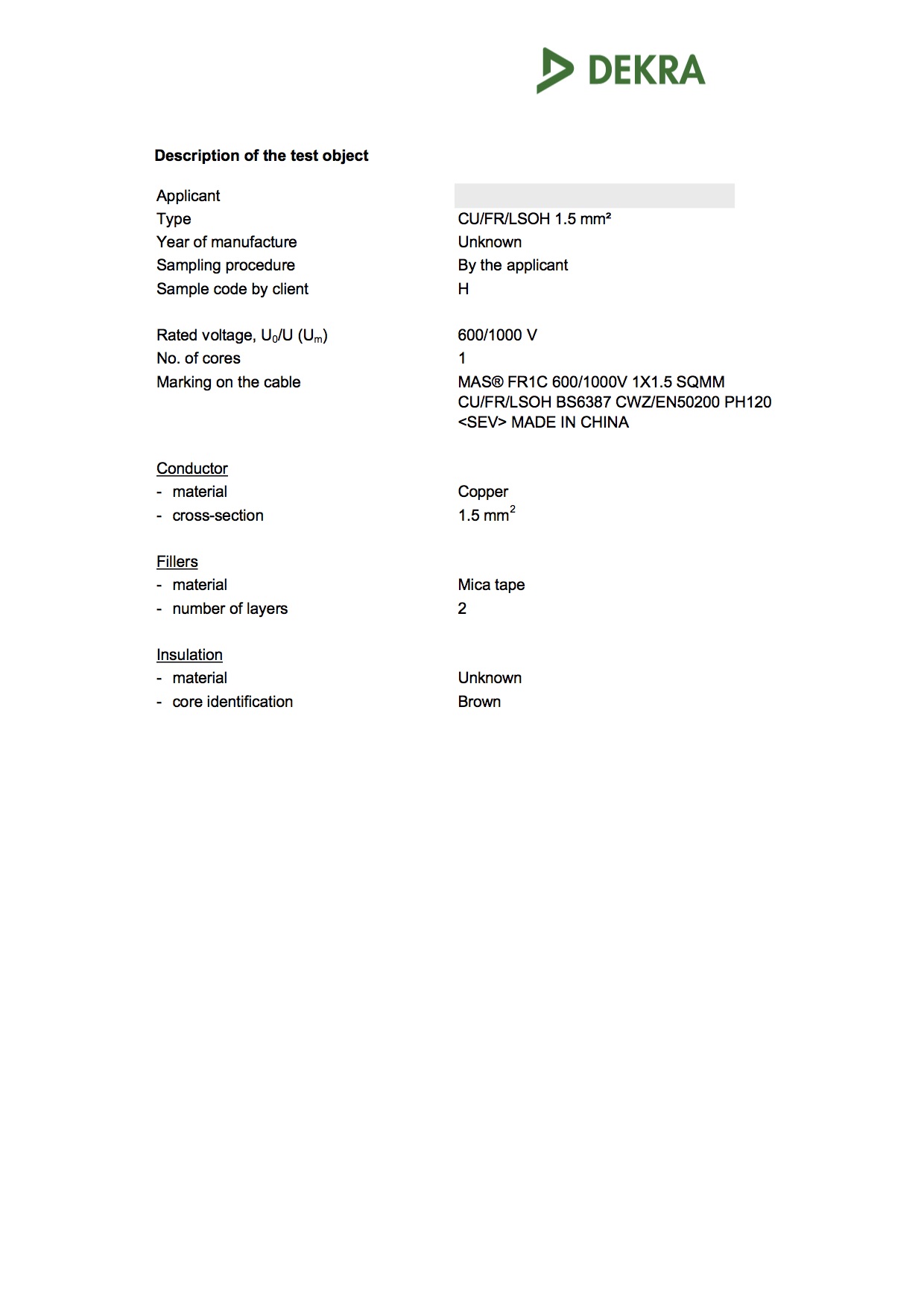

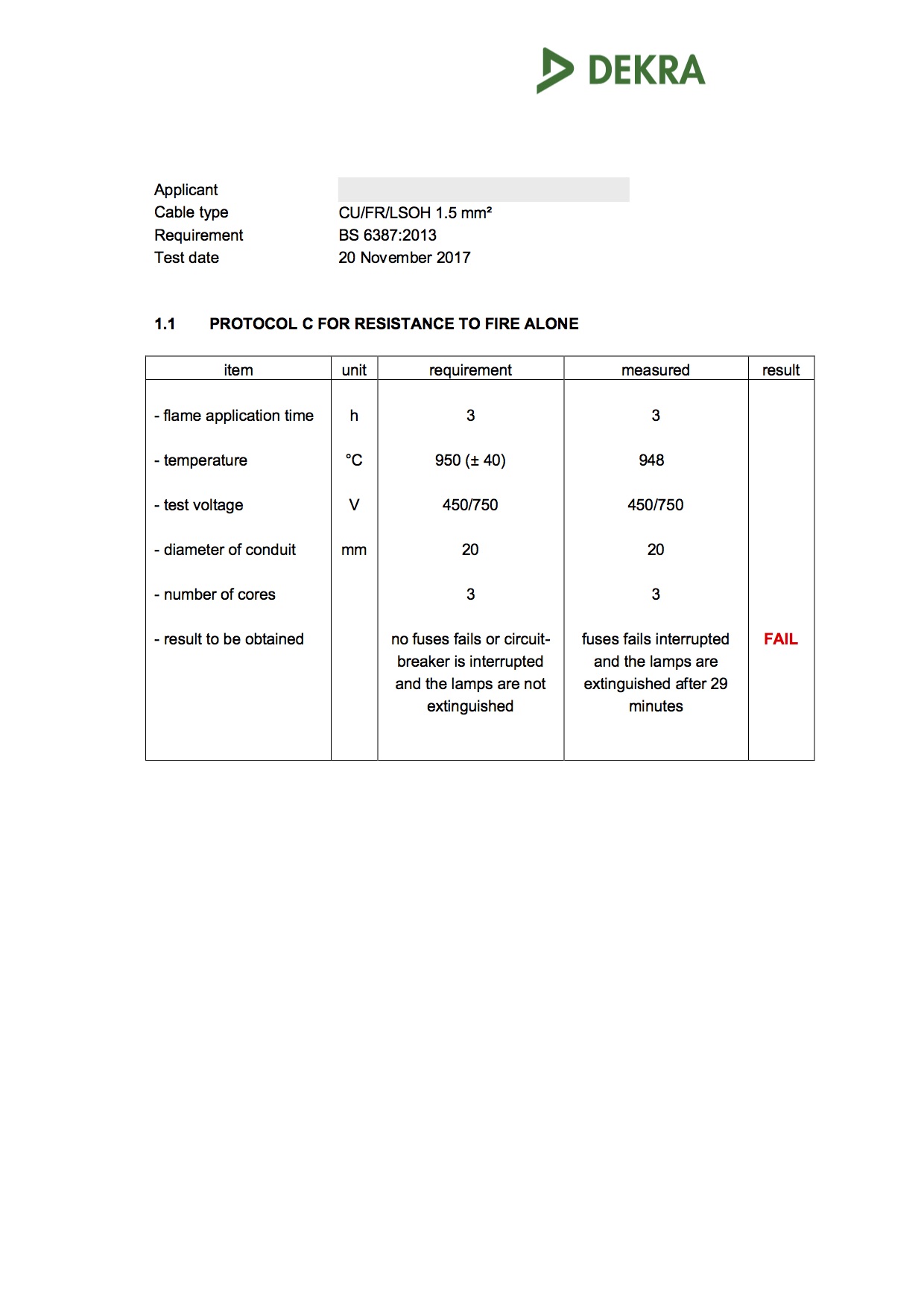

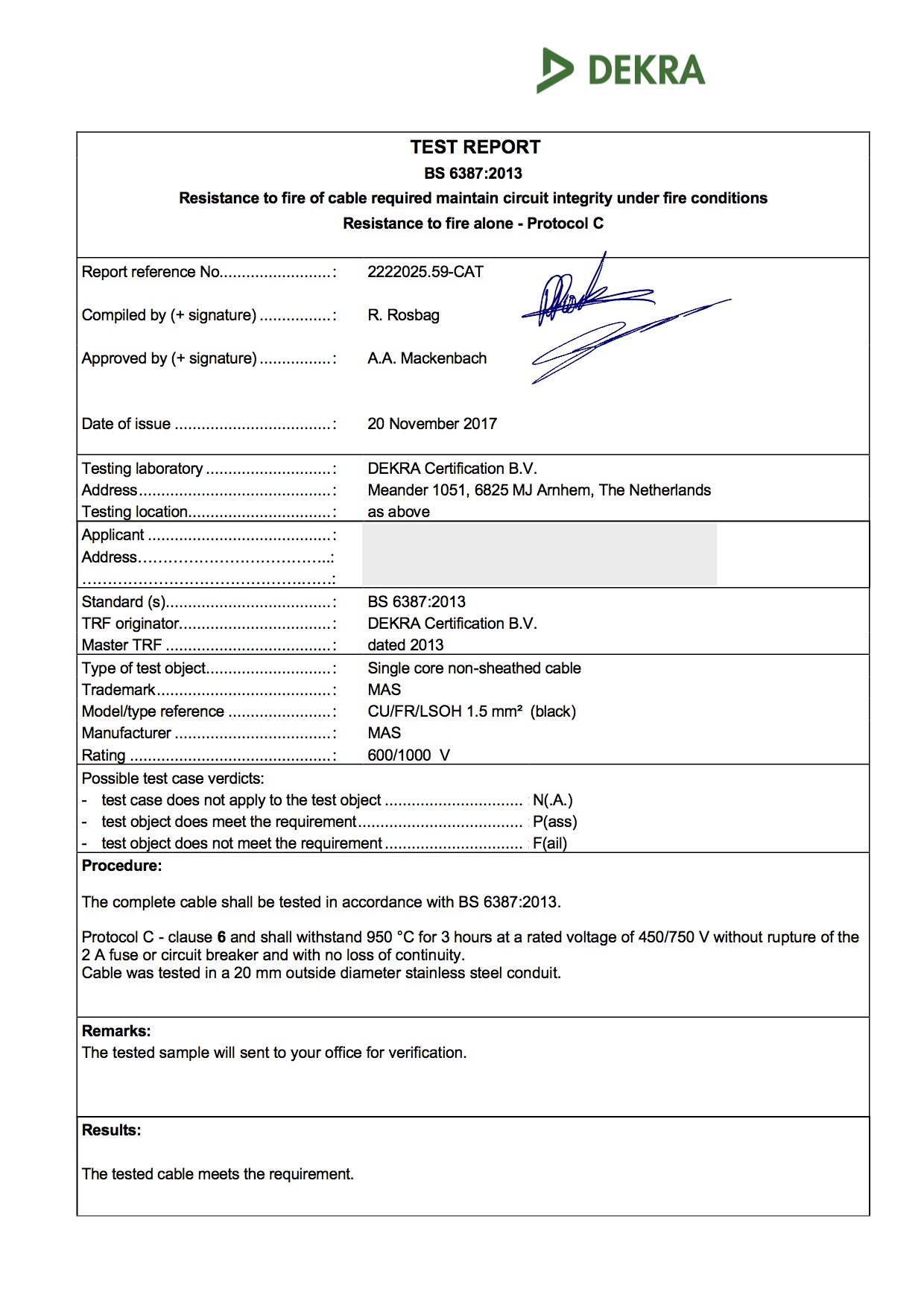

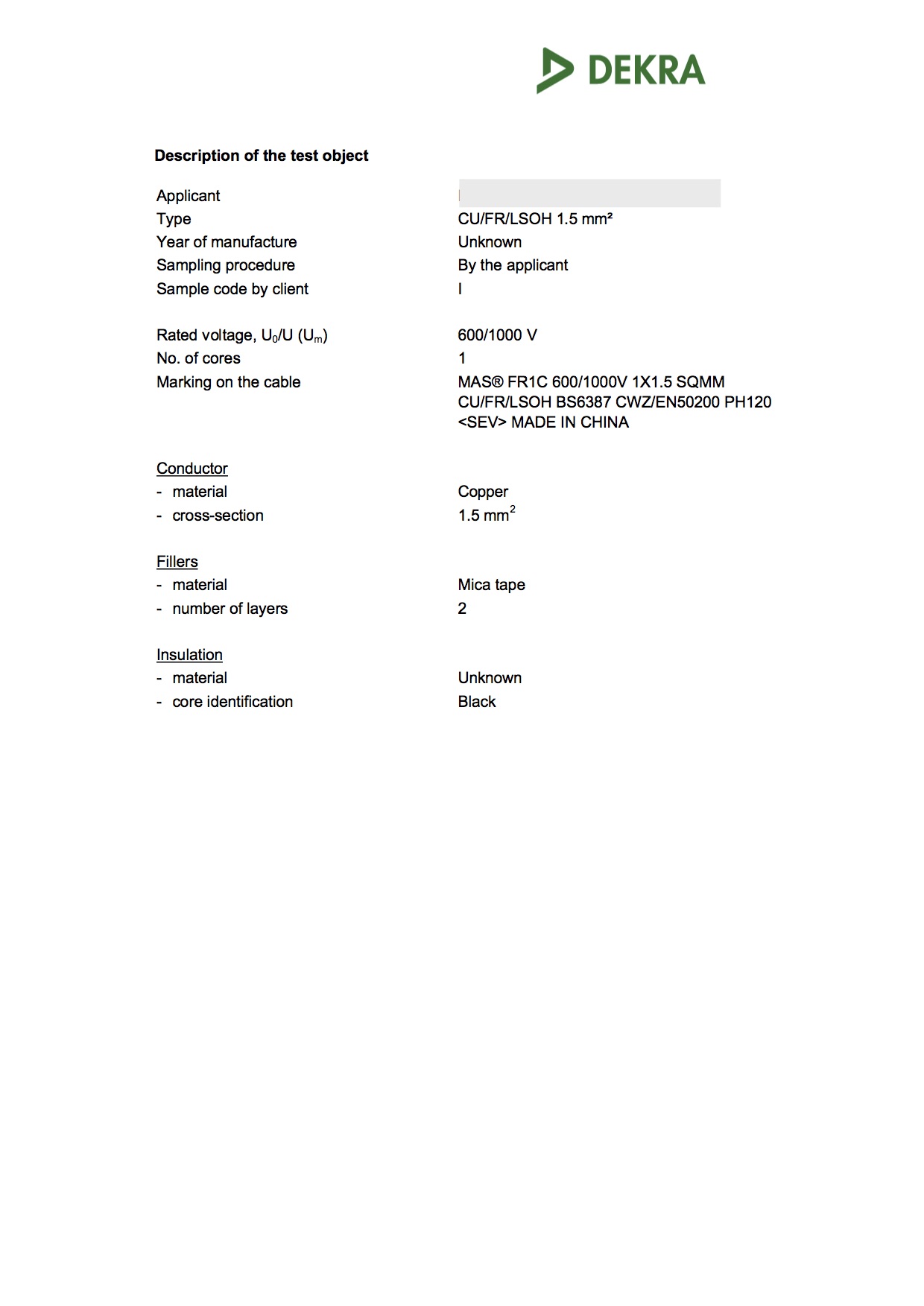

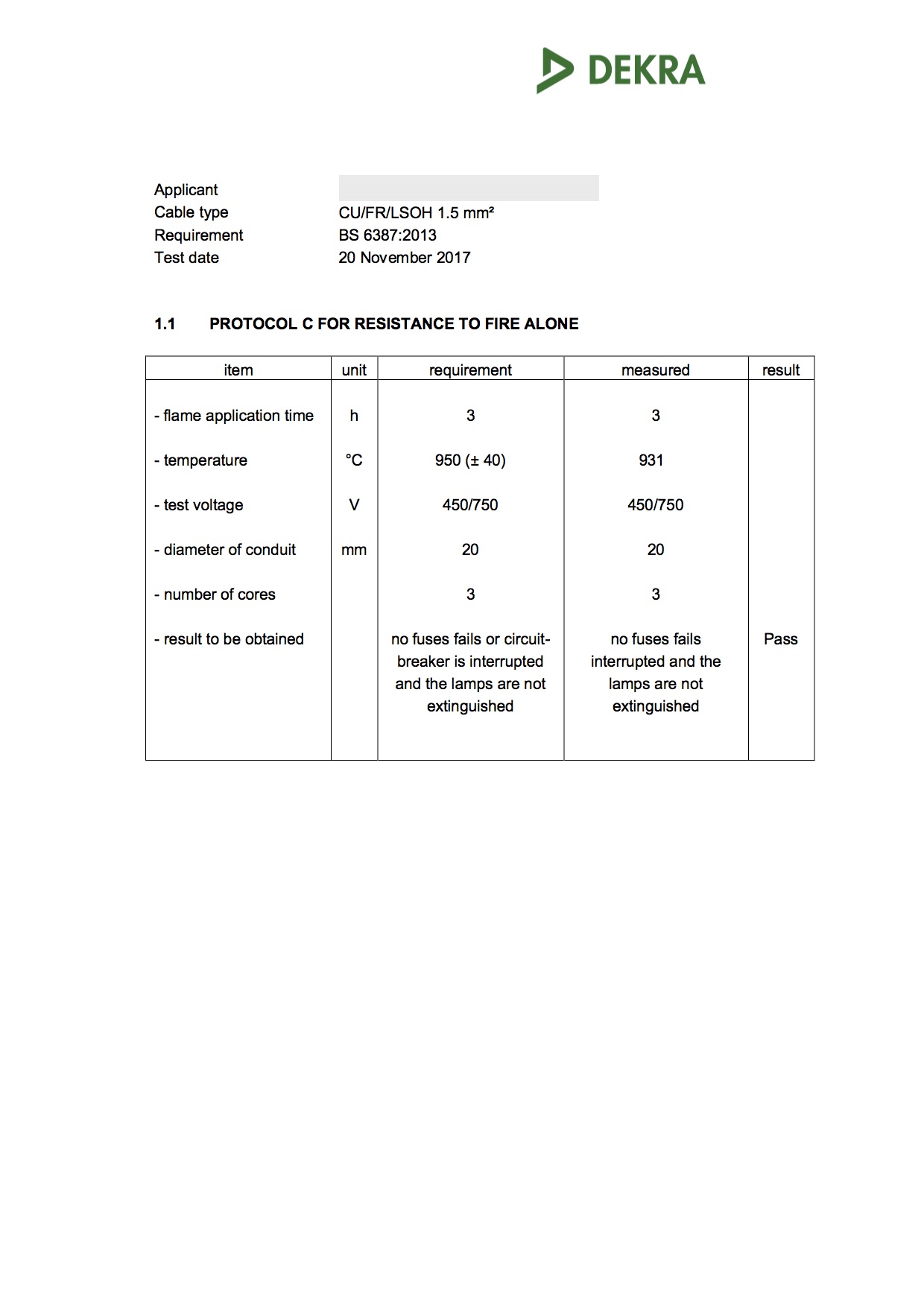

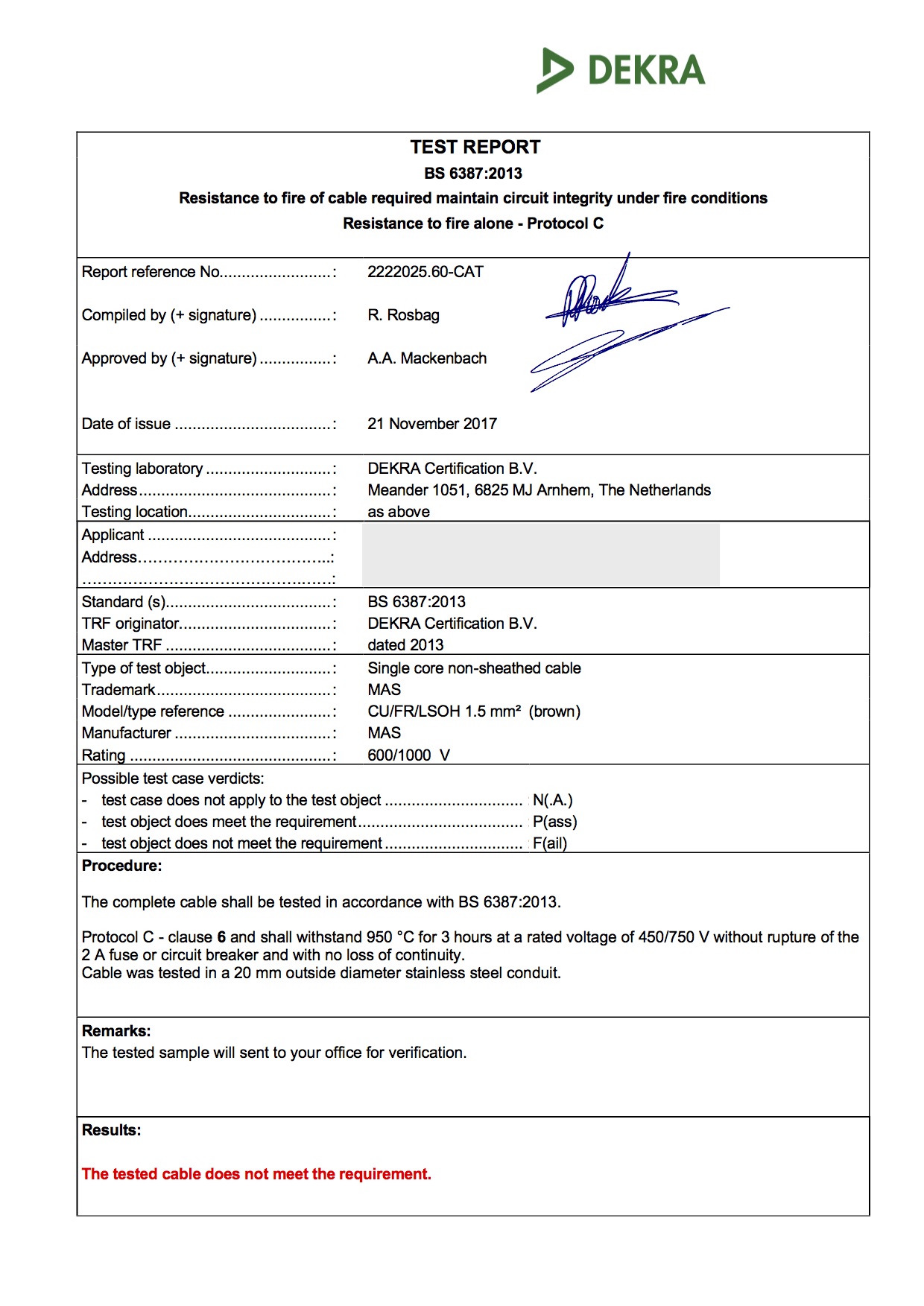

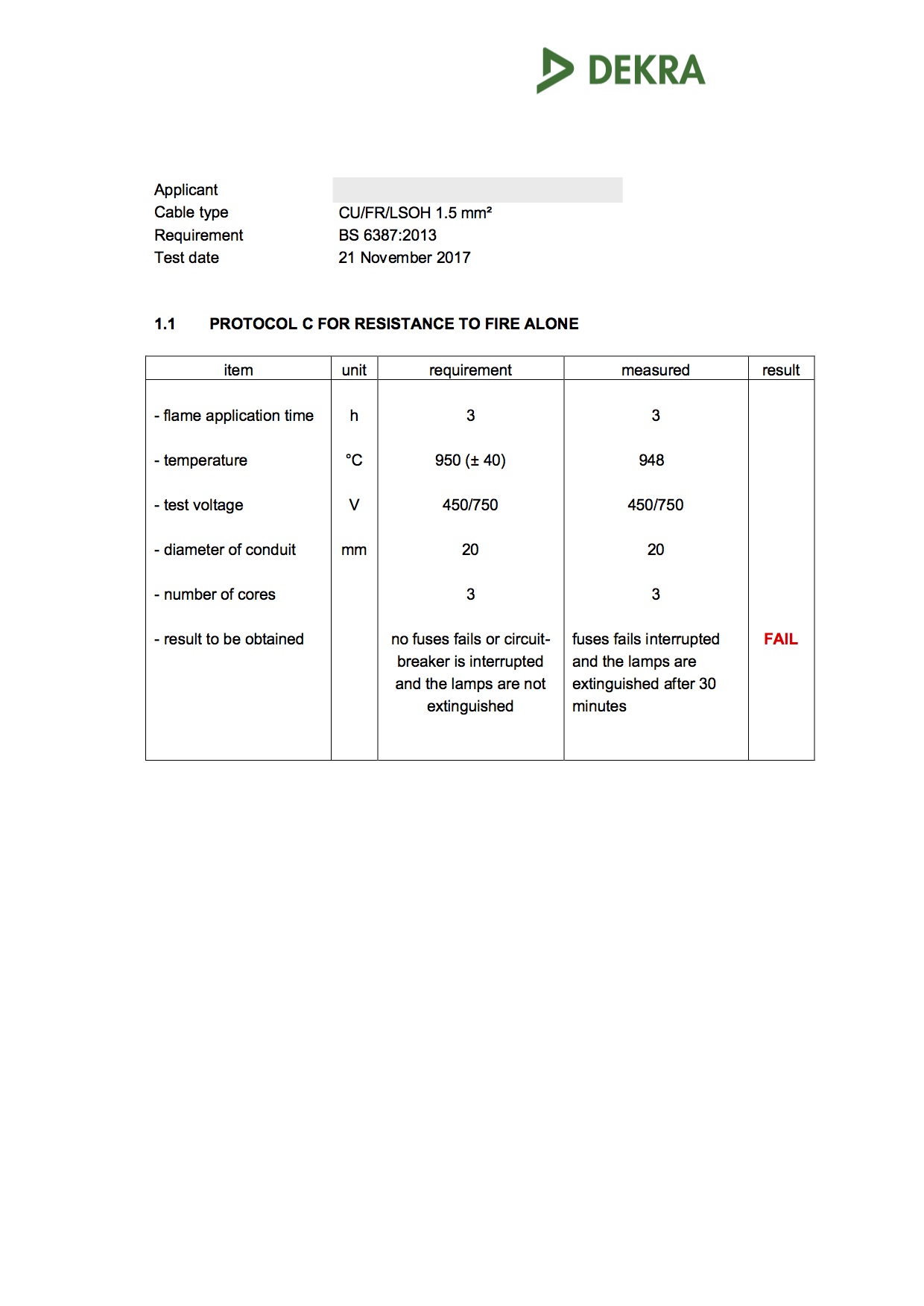

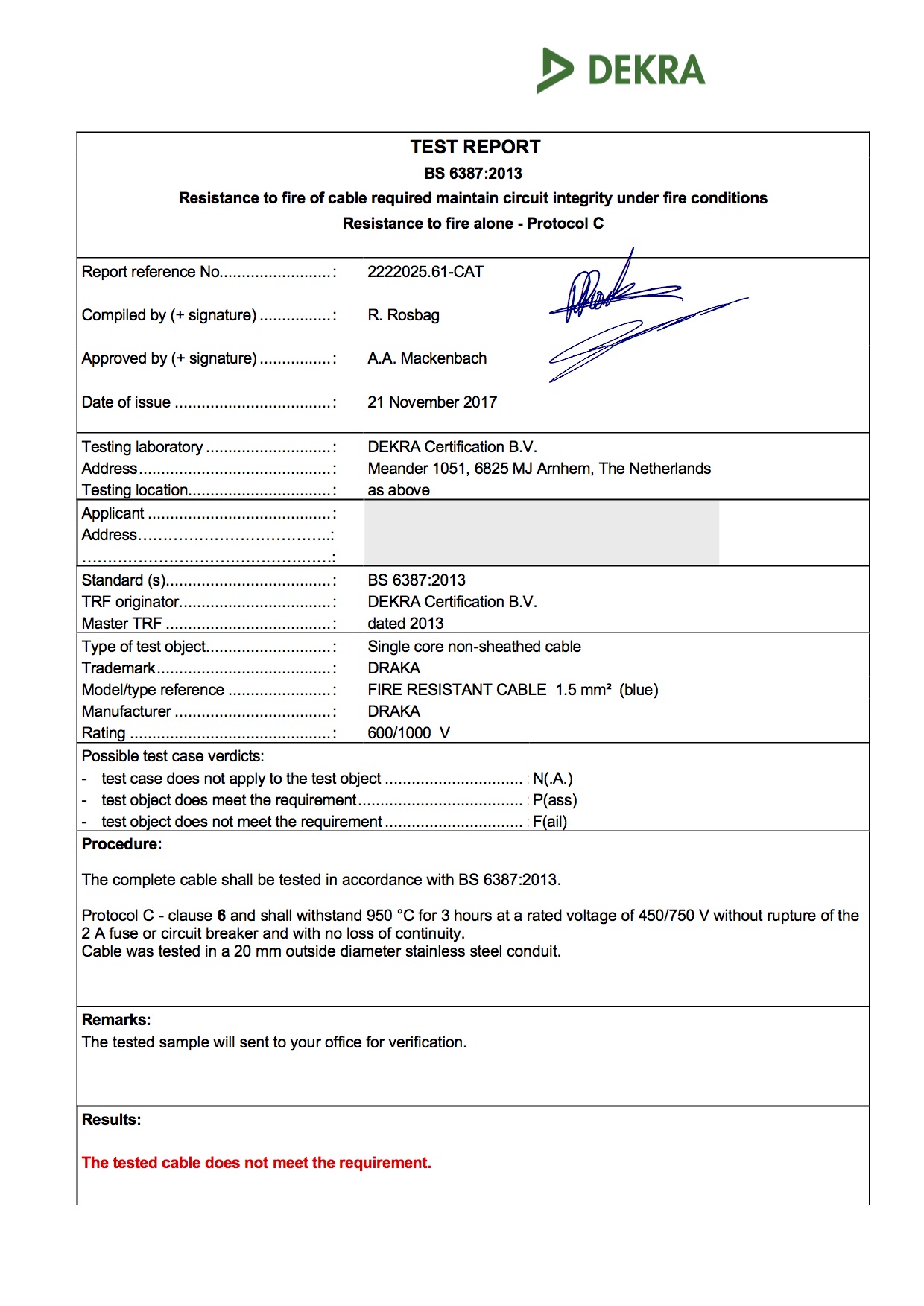

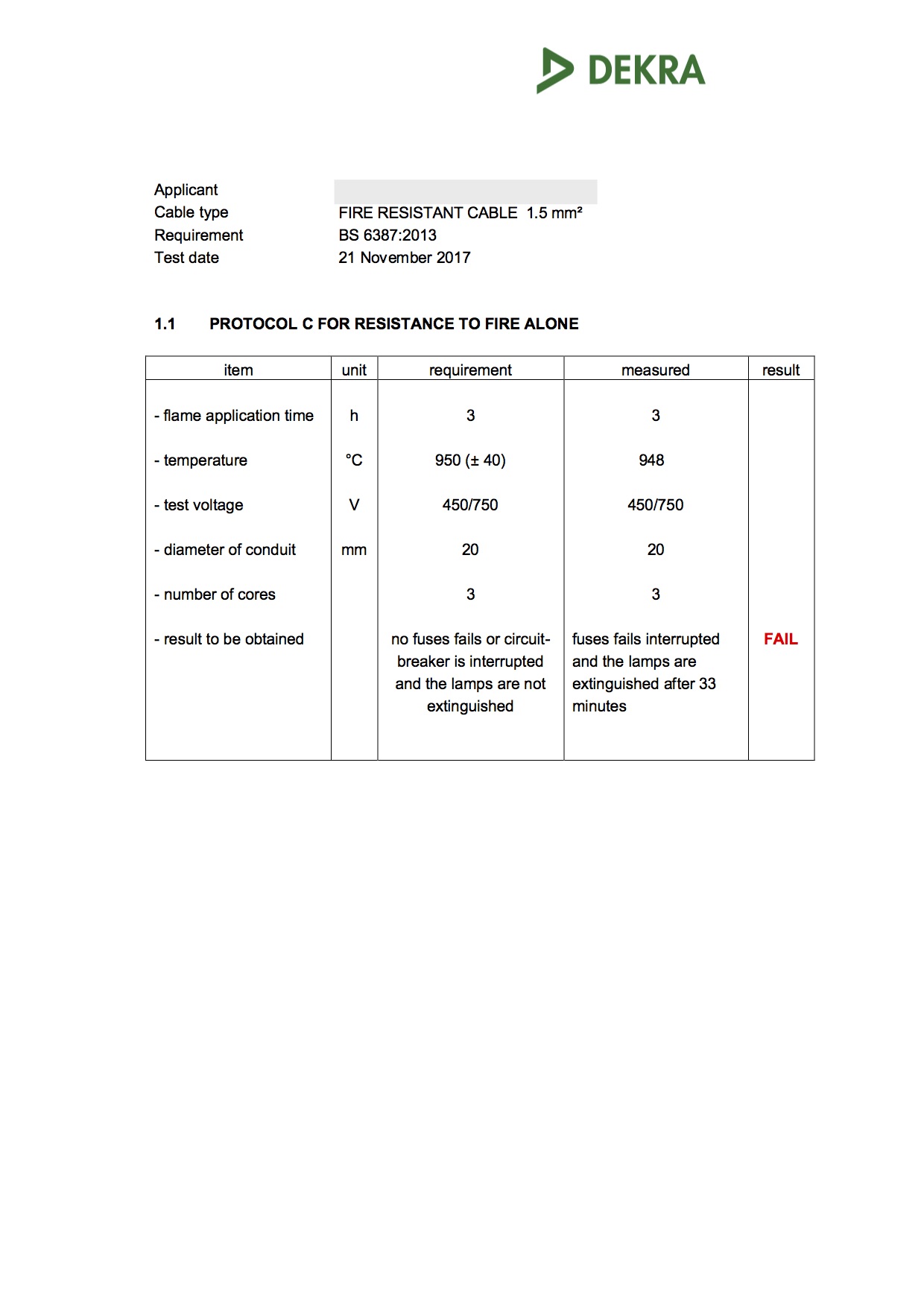

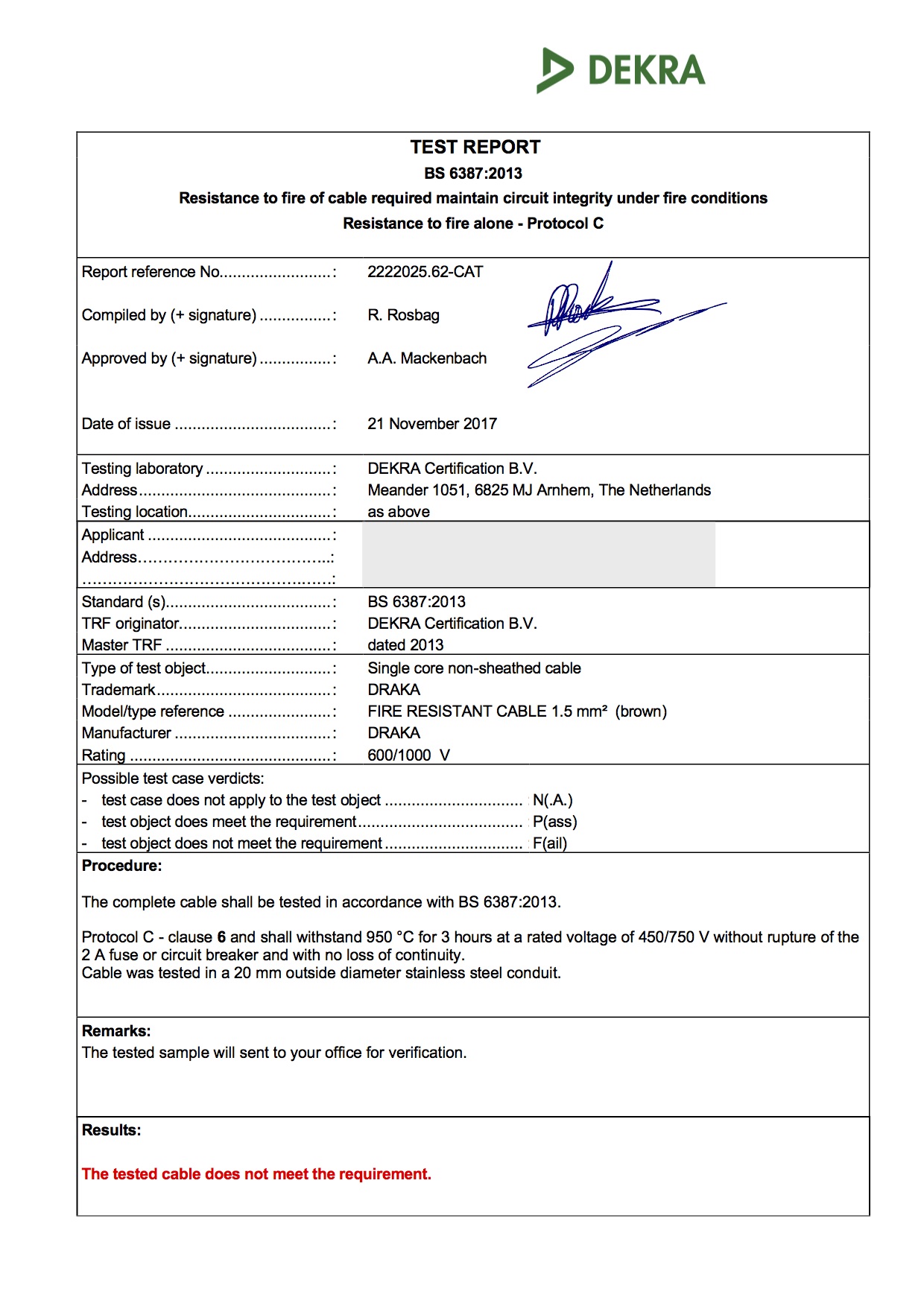

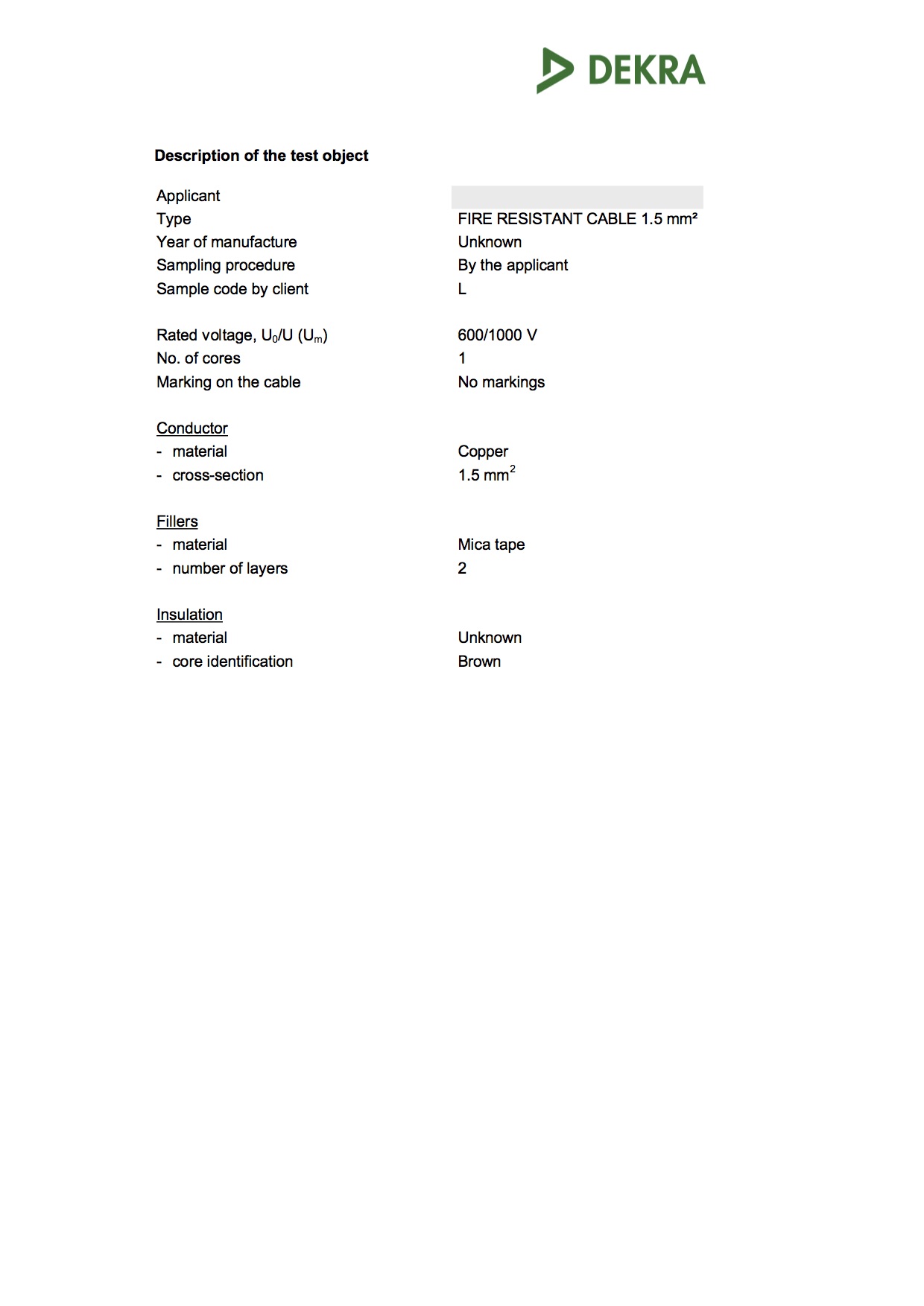

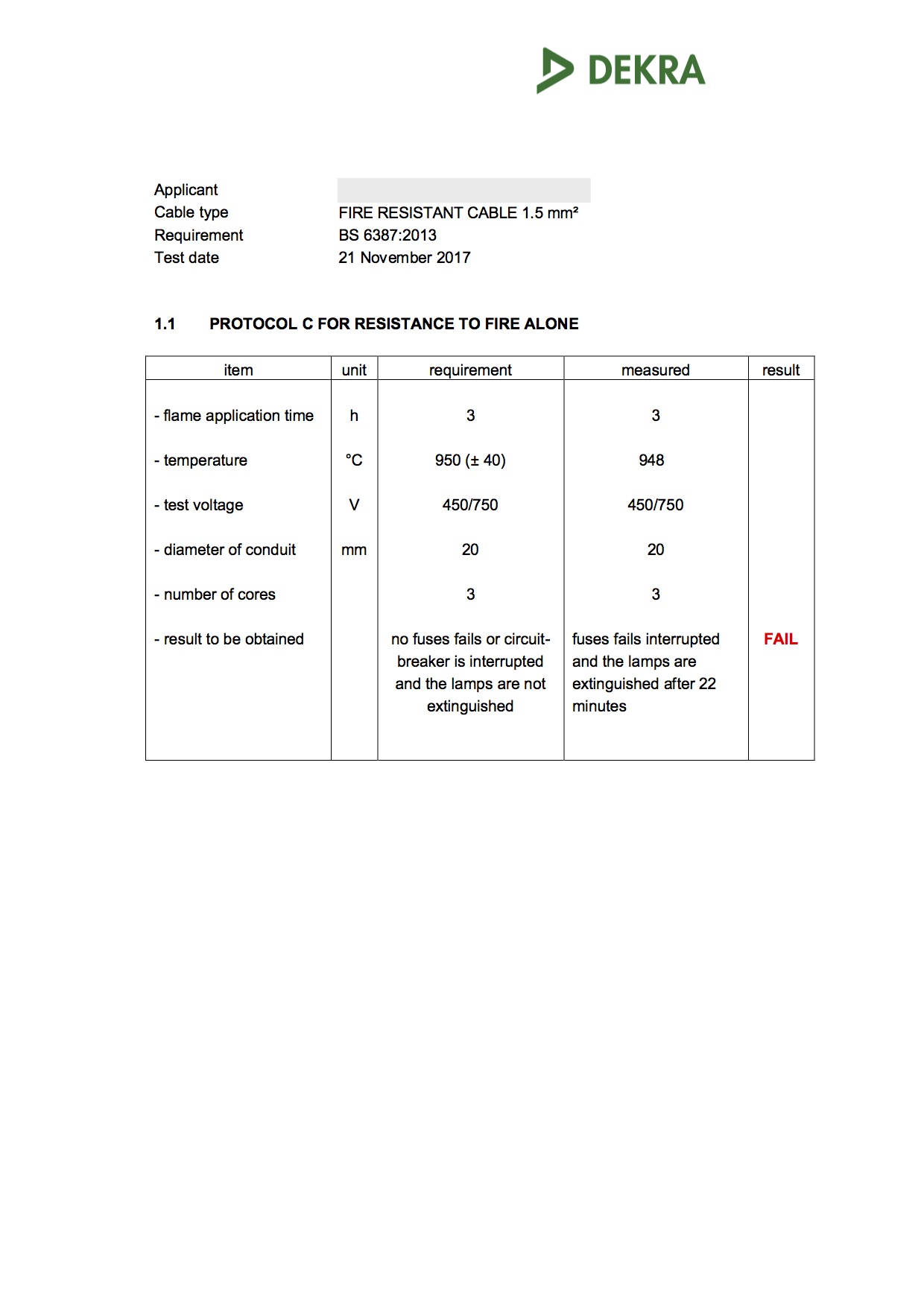

They were sent to a laboratory in the Netherlands owned by Dekra, a testing, inspection and certification services provider, last November to undergo the British Standard BS6387 Category C tests, which require electricity cables to maintain power supply for three hours in a 950-degree fire.

Results show only three samples met the required standards, while the other nine all stopped conducting electricity in 22 to 63 minutes into the tests, including five obtained from Tuen Mun Hospital, two from CityU and one each from the Choi Tak Estate and Hong Kong Children’s Hospital.

The samples cover five major cable brands, including Chinese-made Hong Kong brands MAS and Keystone, British-made Italian brands Prysmian and Draka as well as BICC from the United Arab Emirates.

According to industry sources, Keystone has about 30 per cent market share in Hong Kong and has supplied many Housing Authority projects. The second and third largest brands are Prysmian – which is widely used for commercial buildings, MTR projects and major infrastructure works – and MAS – which supplies the Architectural Services Department. Together with Draka and BICC, the five brands dominate more than 80 per cent of the Hong Kong market and have supplied cables for numerous public and private developments including, housing estates, luxury apartments, the airport, train stations, hospitals, schools and hotels, etc.

All 12 samples were collected by a qualified professional under the observation of FactWire reporters and were originally connected to existing fire safety installations, except a BICC sample, which was collected from the storage compound at the Hong Kong Children’s Hospital construction site.

The qualified professional had also ensured that the functioning of the fire safety installations were not affected.

The type of cables tested, which has a cross-sectional area of 1.5 square milimetres, is typically used in fire alarm systems, emergency lighting and ventilation, as well as emergency signaling systems which support backup power supplies and CCTV.

Except for MAS, which is accredited by the International Electrical Commission, all of the manufacturers have received certifications from the Loss Prevention Certification Board, indicating their fulfilment of the BS6387 standard.

FactWire had contacted the cable manufacturers and their agents last month for responses on the test results. Emil Yu Chen-on, general manager of Keystone and president of the Hong Kong Electrical Contractors’ Association, declined to comment, while Michelle Electrical Supplies, the manufacturer of MAS cables, also did not respond to the requests.

After requesting test reports and leftover cables from FactWire, the Hong Kong subsidiary of Prysmian Group, which owns the Prysmian and Draka brands, said 10 identical samples collected from its warehouses in Britain and Hong Kong had passed tests conducted by its UK laboratory. It also questioned the test equipment, methods and procedures used by Dekra and that whether the cables were damaged during installation and removal.

Ducab, the manufacturer of BICC cables, also said its samples had passed fire tests carried out in its own laboratory. The samples tested include five identical cables – each from a different batch – from a Hong Kong warehouse, two 2.5-square millimetre thick cables from the Hong Kong Children’s Hospital construction site, one from its stock in Dubai and a leftover cable provided by FactWire.

Since the leftover, which is about 2 metres long, was not long enough to be separated into three 1.2-metre long sections for testing as required, Ducab said it substituted with an identical cable.

A veteran electrician, who wishes to remain anonymous, said all 12 samples were fit for use after inspecting their leftovers. He said the cables did not appear to have been stored in a humid place as there was no discolouration or hardening of the sheaths or the wires underneath.

But he admitted it was impossible to determine whether the fire-resistant cables met relevant standards with the naked eye. Inspectors would only check the brand, model and quantity when a batch arrived on site, he said.

He said some brands were known to be of better quality than some others, but he feared the problem might be more widespread given that all major brands had failed the testing.

‘With improved security at the construction sites nowadays, it is rare that construction materials are swapped with inferior products – which are expensive to make – or stolen goods. The problem with the cables appears to be widespread and systematic,’ he said.

Refuting manufacturers’ claims that the cables were damaged during installation or removal, the experienced electrical supervisor said: ‘Workers can’t place the cables slowly. We need to pull them along the conduits and bend them around corners. If fire-resistant cables were that fragile, all fire safety systems in Hong Kong would not work in a fire.’

He added the fact that the BICC cable, which was obtained from a cable reel, also failed the test proved ‘it had nothing to do with the installation process’.

Under current inspection procedures, authorities will only examine submitted test reports and certificates without actually conducting random testing on building materials. This practice has given rise to a loophole where manufacturers could submit so-called ‘golden samples’ for accreditation.

‘Their quality is usually better than that of the products contractors receive, and they can even be manufactured by factories with different technical levels,’ an industry source, who does not wish to be named, said.

‘The common practice is, unless the materials look unusable, they will be accepted as long as the certificates check out.’

As the global engineering industry has yet find a way to solve the problem of ‘golden samples’, some reputable brands may not be absolutely reliable, he added.

Citing the Kobe Steel and the Xi’an Metro wiring scandals as examples where the faulty products all managed to obtain certifications, he believed only unannounced materials testing and inspection led by the government could reduce the chances of cheating.

Following FactWire’s earlier report last April revealing that the fire-resisting cables from the On Tat Estate also failed safety tests, acting transport and housing secretary Yau Shing-mu told a legislative councillor at the time that the Housing Authority had conducted a functional test on the fire safety system in the estate under the observation of the Fire Services Department (FSD) and concluded that the system was operating normally.

However, a source who is responsible for the construction site told FactWire that government officials only visited the site once to check the certification documents and did not take away any cable samples for testing.

When contacted by FactWire for response on the latest test results, the FSD said, according to an opinion provided by an overseas accreditation body, removing cable samples from an installed fire equipment could damage the structure of the cables, hence affecting the test results and their representativeness. But the department did not specify the source of the opinion nor its full text.

It also did not explain why the BICC sample, which was taken directly from a storage compound at the Children’s Hospital construction site and had not been used, also failed the test, only saying it had referred FactWire’s enquiry to the Architectural Services Department.

The FSD stressed that, when inspecting a fire safety equipment, it would examine the documents for the cables as well as their markings, certificates and test reports after they had been installed.

It added the current product certification system was locally and internationally recognised and that if any fire resistant cables were found to be substandard, it would refer the case to law enforcement.

However, the FSD did not answer questions as to whether it would conduct safety tests on fire-resistant cables, nor how it could ensure they meet required standards without conducting any tests.

The Electrical and Mechanical Services Department said, under the current material inspection procedure, contractors were required to submit valid test reports and certificates issued by accredited laboratories which would be reviewed by its engineers. It also said it had strengthened the measures since last year by starting to review cable markings before they were allowed to be installed.

The Electrical and Mechanical Services Department said, under the current material inspection procedure, contractors were required to submit valid test reports and certificates issued by accredited laboratories which would be reviewed by its engineers. It also said it had strengthened the measures since last year by starting to review cable markings before they were allowed to be installed.

The testing method adopted by Dekra was in line with a guideline published by the British Standards Institution known as ‘Test Method for Resistance to Fire of Cables Required to Maintain Circuit Integrity under Fire Conditions’ in 2013.

According to the guideline, the cables must be tested in a steel conduit with a outside diameter of 20 millimetres and has to maintain power supply in a fire for three hours at 950 degrees to satisfy the requirement of BS6387.

The second and third repeat tests were not conducted due to insufficient length of the cables obtained by FactWire.

Information such as brand names, voltage, verification codes, international standards and model numbers was marked on the exterior of the cables. Dekra did not record the markings on three of the samples as the embossments were obscure.