An official distribution of disposable masks to the public started last week. Yet, FactWire found out in a recent investigation that the production and processing of these masks by at least one of the manufacturers may not meet hygiene standards.

An official distribution of disposable masks to the public started last week and yet, authorities have released limited information on the masks’ costs and manufacturers. In a recent investigation, FactWire found out that the production and processing of these masks by at least one of the manufacturers may not meet hygiene standards.

The masks, which come in a pack of ten, are among those being distributed to each residential address in Hong Kong. The government said these are the first batch of masks procured under the Local Mask Production Subsidy Scheme.

Creative International Technology Limited is one of the manufacturers approved for two production lines under the scheme. However, its processing of some of the masks is suspected to not meet the hygiene requirements of a cleanroom. Its workers were also filmed on camera packing the masks directly on stacks of paper boxes and cardboards.

The Commerce and Economic Development Bureau said the Hong Kong Productivity Council has been conducting site visits regularly to monitor the mask production. It said the workers were wearing face masks, protective gowns etc. during its visit.

However, from FactWire’s investigation, some of the workers did not wear protective gowns even inside cleanrooms.

Located in Kwai Hing’s Wah Tat Industrial Centre, Creative International Technology’s mask production venue is a series of six connected units. The outside corridor was filled with paper boxes labelled “Together, We Fight the Virus!”, a slogan used by the government during the epidemic.

FactWire obtained photos and video clips showing that the venue’s interior is divided into three areas, namely cleanrooms for production and packing, the storage area and the office. At least 30 workers were on duty at the time the photos and videos were taken.

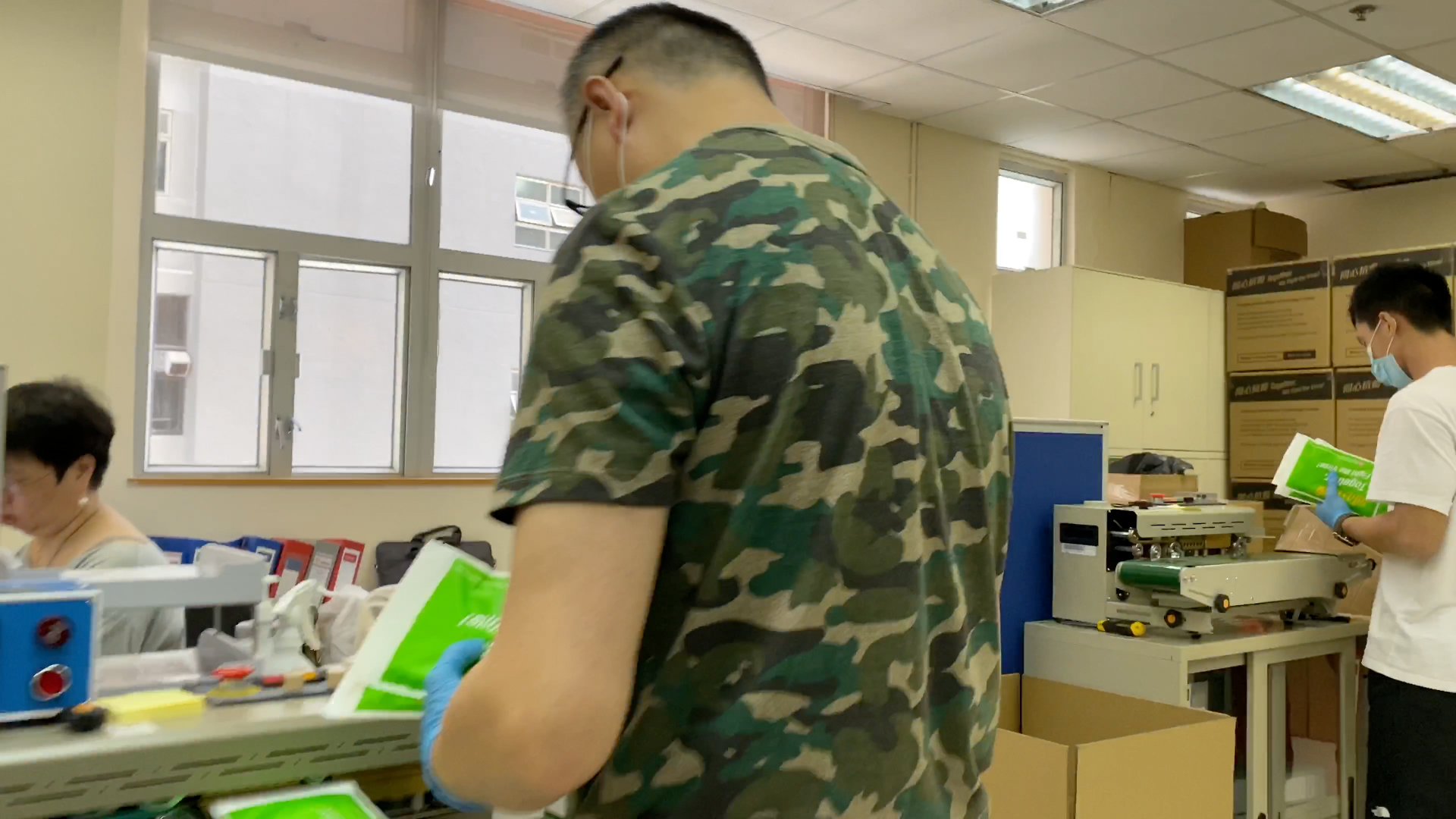

The videos show a mask production machine placed in the innermost of one of the cleanrooms. Some of the workers were wearing face masks, head covers and protective gowns. A man, however, was just in his casual wear without putting on any protective gown or head cover.

In another cleanroom, about ten workers were in their casual wear without their protective gowns on. Most of them had on their gloves and head covers, but three did not put on their head covers and another worker’s long hair was not entirely covered. They were packing finished masks into green packaging bags printed “Together, We Fight the Virus!”.

Two other smaller cleanrooms were unused. One of them had several paper boxes in it. In contrast to these empty cleanrooms, seven to eight workers did the packing in an area outside the cleanrooms, sitting around a ‘table’ formed by stacks of cardboards and paper boxes with over a thousand yet-to-be-packed masks perched upon it. The piles of masks were exposed to the air.

A source who had once worked in the area told FactWire that she had witnessed workers picking up accidentally dropped masks from the floor and packing them together with other masks.

The workers who were packing outside the cleanrooms had on their face masks and gloves, but not their head covers and protective gowns. There were also other workers passing by the area and a washroom less than three metres away. Paper boxes were stacked upon each other all over the place.

The bags of masks were then sent to be sealed by a machine stationed approximately five metres away, a location close to the main door. Workers responsible for the sealing only wore face masks and gloves.

Based on observations from outside the main door, people were seen easily entering through the main door without washing or sanitising their hands. Temperature checks were also absent.

The packs of masks, after being sealed, were put into the paper boxes labelled “Together, We Fight the Virus!”.

Novetex Textiles Limited, in charge of the sanitising and packing of the government’s reusable CuMask+, had earlier shown the media how CuMask+ were sanitised and packed in cleanrooms. All cleanroom workers had on face masks, head covers, protective gowns and shoe covers. Sanitisation and temperature checks were conducted at every entrance and exit.

Branding Works Air is one of the local companies that builds cleanrooms. Its head of engineering Franco Lee told FactWire that qualified cleanrooms must achieve the international standard of Class 8 under ISO 14644-1, such that pressure and airflow, etc. are controlled.

However, Lee stressed that even when the hardware machinery is up to standard, the cleanroom can hardly be qualified without proper management and monitoring. He gave the example of workers having lunch inside the cleanroom, which breaks qualification standards.

Lee added that in order to maintain Class 8 under ISO 146644-1, an ISO 13485 quality management system must be followed at the same time. It requires anybody entering cleanrooms to wear a head cover, a protective gown and shoe covers, etc. Some companies even require a change of pants. Anybody entering would first have to go through an air shower to avoid carrying any particulates into the cleanroom.

Section 6.4.1 of ISO 13485:2016 states that the organisation should monitor and control the work environment. This includes documenting requirements for health, cleanliness and clothing of personnel if contact between such personnel and the product or work environment could affect the safety or performance of the medical device. Section 6.4.2 also states that it should maintain the required cleanliness during the assembly or packaging of sterile medical devices. Section 7.5.11 states that the organisation should protect the product from alteration, contamination or damage during processing, storage, handling and distribution.

In response to FactWire’s enquiry, the Commerce and Economic Development Bureau said that the Hong Kong Productivity Council has been monitoring the production of masks over the past months through site visits and examination of the reports submitted by manufacturers. It said the Hong Kong Productivity Council “had seen relevant personnel wearing appropriate protective equipment, including face masks, protective gowns, head covers, gloves and shoe covers” during its site visits.

The Bureau did not respond to FactWire about the number of companies involved in supplying the batch of masks currently being handed out to the public.

A male staff member of Creative International Technology Limited told FactWire in a phone call that its workers are mandated to wear protective gowns and head covers, etc.. He said the packaging procedure should be done within cleanrooms “as much as possible”.

When told that the company’s processing of masks may not meet hygiene standards, the staff member said that ‘it might be slander’.

FactWire requested a response from the company’s person-in-charge. No comment has been received so far.

In view of the surge of demand for masks, the government used the Anti-epidemic fund to subsidise 20 production lines under the Local Mask Production Subsidy Scheme. Company applicants are required to have their own production equipment, raw materials and an owned or rented production venue and cleanroom in Hong Kong. Applicants also have to prove their capability to comply with Level 1 of ASTM F2100, the ISO 13485:2016 quality management system standard and to achieve ISO Class 8 under ISO 14644-1 for the cleanroom.

Out of over a hundred applicants, 15 companies were approved for obtaining the subsidy. This includes Creative International Technology Limited who received a total of HKD 4 million for two production lines. The company is expected to supply 4 million masks to the government every month for a year.

Chief Executive Carrie Lam announced at the end of last month that a pack of ten disposable masks would be distributed to each of about 28.8 million residential addresses in Hong Kong, starting from June 30. They are said to be the first batch of masks procured under the Local Mask Production Subsidy Scheme, although details of respective manufacturers and their exact costs remain unclear.

According to Company Registration, Creative International Technology Limited was founded on August 15, 2019. Its shares were transferred to Chan Kim-fai and Mok Ka-hei on February 28, 2020. The company’s address was changed on the same day into 92-98 Parkes Street in Jordan, where Oriental SAUNA SPA is located.