Testing has found excessive carbon in the lid of a steam generator, making it prone to cracking

A potentially critical flaw has been found in another important component of Taishan nuclear power plant, raising further safety concerns over the troubled project following a series of revelations by FactWire.

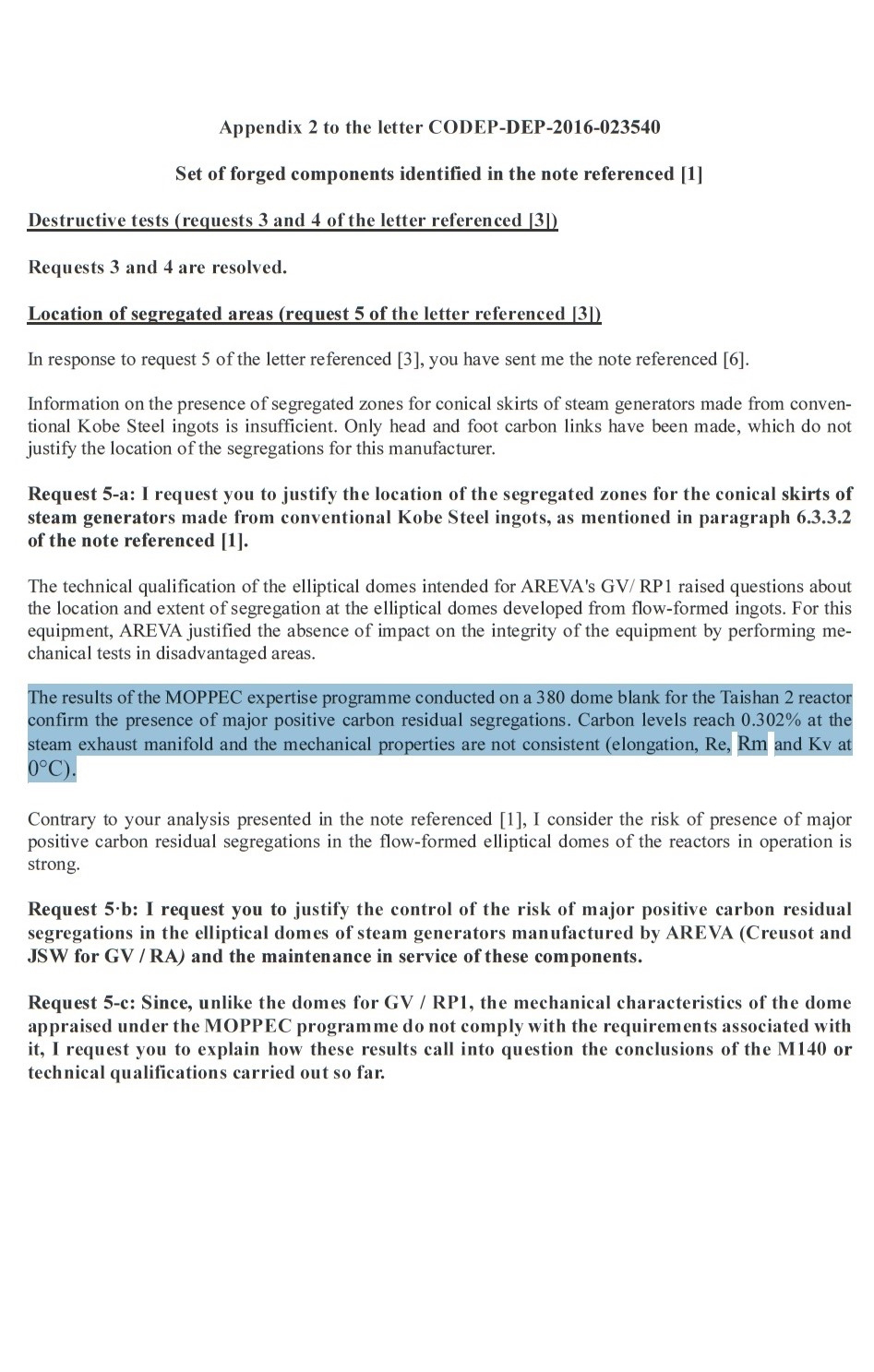

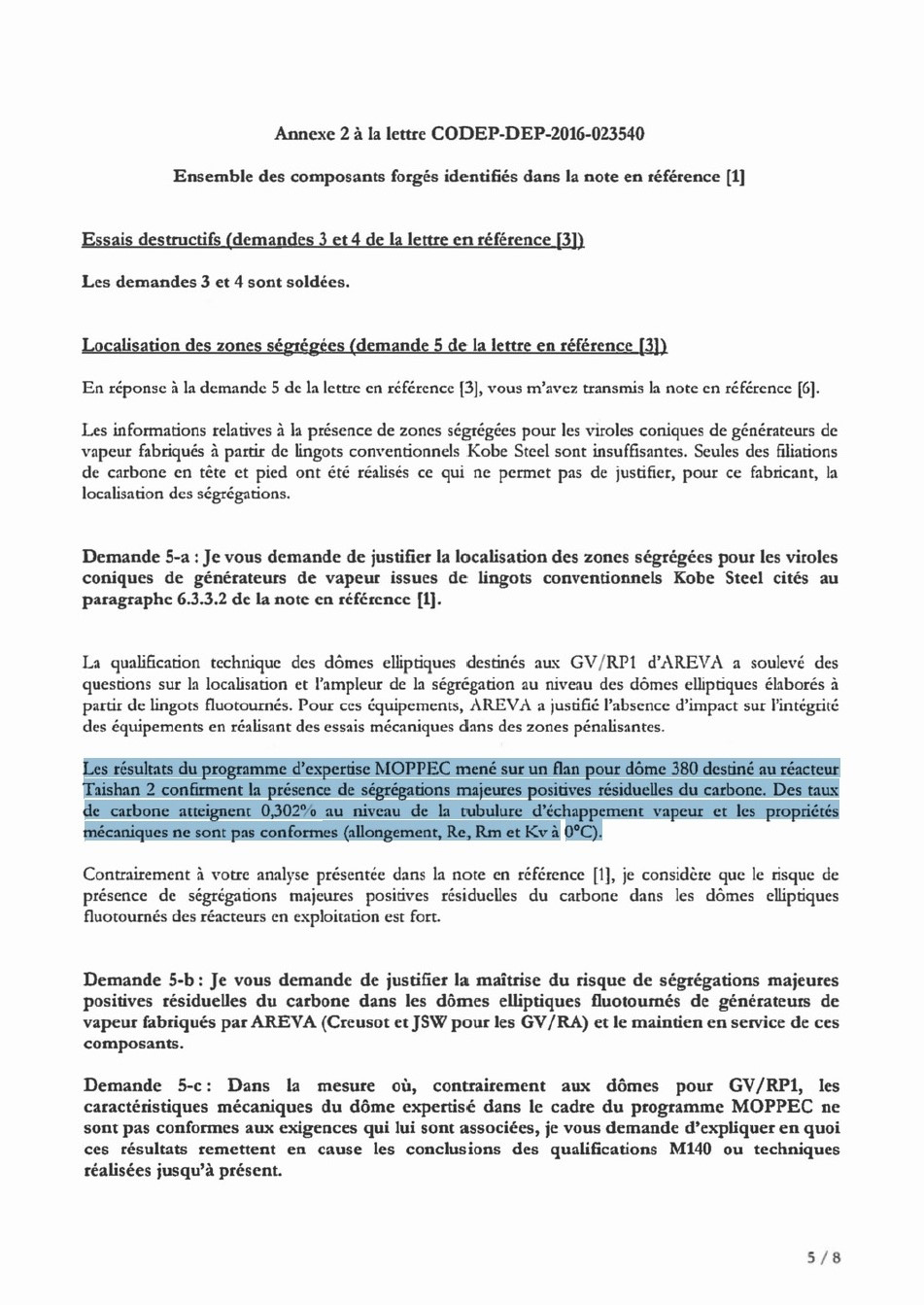

The component in question is the elliptical dome, also known as the upper head, of a steam generator at Taishan. Testing has found excessive carbon in the part, making it prone to fast fracture under heat and high pressure, according to a letter from the French Nuclear Safety Authority (ASN).

At France’s Flamanville nuclear power plant, the upper and lower heads of the reactor pressure vessel were discovered to have similar carbon anomalies in April 2015, prompting questions over the safety of identical components at the Taishan plant, which came from the same supplier.

The French authorities have decided in October to replace the problematic vessel upper head by the end of 2024 with a new one, which will take seven years to manufacture.

Meanwhile, China General Nuclear Power Corporation (CGN), which is developing the Taishan project with French utility Électricité de France (EDF), insisted at the time that inspections did not find any problems in any of the plant’s components.

But according to documents seen by FactWire, result from the ‘prediction model for properties of large forgings hot formed by upsetting operation’, also known as Moppec, conducted by supplier Areva showed that the steam exhaust outlet of Taishan Unit 2’s steam generator upper head contains carbon content of 0.302 per cent, exceeding the required level of 0.22 per cent set by the RCC-M standard.

RCC-M is an international standard code for the design and construction of pressurised equipment relating to the nuclear island of pressurised water reactor power plants. The code, designed by standards organisation French

Association for Design, Construction and Surveillance Rules of Nuclear Power Plant Components (Afcen), has been adopted by 116 nuclear plants around the world, including Flamanville and Taishan. The standard was later incorporated in the French Order on Nuclear Pressure Equipment (ESPN) in 2005.

In the letter to EDF, Rémy Catteau, director of nuclear pressure equipment division at the ASN, demands the state-owned electricity company to justify the excessive carbon content found in the steam generator upper head made from Kobe Steel ingots.

He added that ‘the risk of presence of major positive carbon residual segregations’ in identical components of other operating reactors was strong.

The letter does not explain whether the issue was caused by the material supplied by Kobe Steel or in fact its forging process.

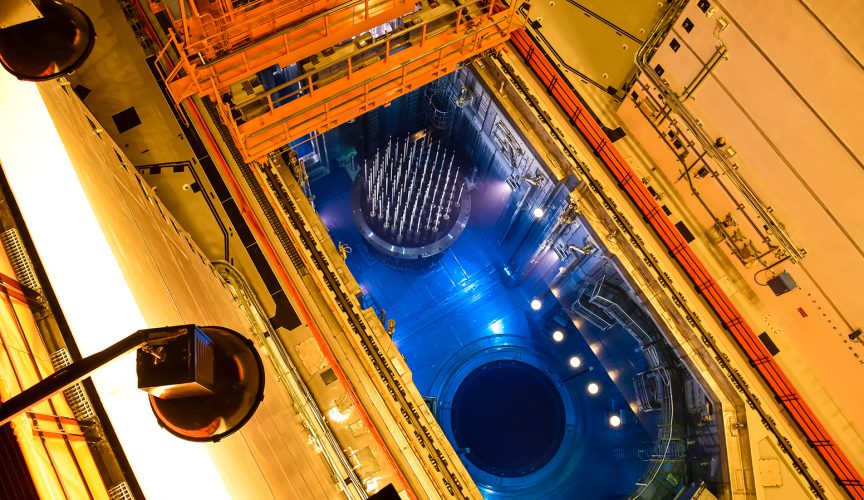

A steam generator is a nuclear safety-related component. As a primary coolant loop equipment, it functions as a heat exchanger between pressurised water in the primary loop and water in the the secondary loop which then converts water into steam to drive the turbine. It is required to withstand temperatures up to 330 degrees and 155 bars of pressure in the reactor.

The flawed generator upper head was commissioned by Areva and manufactured by Japan Steel Works (JSW). Out of the four steam generators at Taishan Unit 2, the two upper heads assembled by Dongfang Electric (Guangzhou) Heavy Machinery were made by JSW, whereas information on the manufacturer of the other two, which were assembled by Shanghai Electric Nuclear Power Equipment, was unavailable.

According to ASN documents, excessive carbon in steel-made upper and lower heads reduces the resistance of the steel to propagation of cracks under extreme temperature and pressure. Cracks in steam generators can directly affect the cooling water supply in the primary coolant loop, resulting in fuel melting and radiation leakage.

Huang Xiaofei, spokesperson for the Hong Kong-listed CGN subsidiary CGN Power, had said in April that components of the Taishan plant met the RCC-M standard and that the 2005 ESPN order was ‘too new’ and ‘controversial’. He also said there were ‘no quality issues’ but only ‘differences between the old and new standards’.

The limit on carbon content has always remained at 0.22 per cent since the issue of the ESPN order in 2005.

CGN had said it expected Unit 1 to be operational by the end of this year, which would followed by Unit 2 in the first half of 2018.

However, following FactWire’s revelation earlier this month, the Chinese state-owned utility then admitted the deaerator in Unit 1 had ‘partial defects’ and would need to be replaced. It has yet to confirm the exact date of Taishan Unit 1’s start-up.

Meanwhile, in a report released on 10 October after two and a half years of investigation into carbon content anomalies, the ASN said that, although the reactor at Flamanville could operate safely with constant extra monitoring, the vessel upper head must be replaced by 2024 latest.

As it is impossible to carry out destructive tests on the already-installed head to detect cracks, the reactor pressure vessel runs the risk of cracking during nuclear fission, which could result in fuel melting in the reactor core and radiation leakage, the report reads.

ASN documents also reveal that excessive carbon concentrations in the vessel upper and lower heads were the result of a problematic manufacturing procedure adopted by their French supplier Creusot Forge. Other vessel heads manufactured by using the same procedure could also face the same problem.

The reactor pressure vessel heads for Hinkley Point C in Britain and another nuclear plant in the United States have been tested to have carbon concentrations between 0.221 to 0.279 per cent, exceeding the regulatory maximum of 0.22 per cent. Flamanville is even worse, at 0.3 per cent.

The carbon contents and quench rates at different depths in the base and covers of a US nuclear power project and Hinkley Point C in Britain (Photo: French Nuclear Safety Authority)

The ASN has informed the Taishan plant, which shares the same design, of the quality issue in April 2015. China’s National Nuclear Safety Administration admitted at the time that the upper and lower heads of the two reactor pressure vessels at Taishan were made by Creusot Forge.

The vessel bodies of Unit 1 and 2 were made by Japanese manufacturer Mitsubishi Heavy Industries in Kobe and Dongfang Electric (Guangzhou) Heavy Machinery in Nansha respectively.

Areva has ordered a new vessel upper head from Japan Steel Works for Flamanville, which will take 71 months to deliver. Installation of the new part will take another four to nine months.

With regard to the existing lower head, the ASN has required Flamanville to conduct in-service inspections, including pre-service inspections and periodic requalification tests, to evaluate the ductile tearing resistance and look for cracks. The area of inspection covers a depth of 20mm from the outer wall of the reactor pressure vessel bottom head.

EDF, which owns 30 per cent of the Taishan project, said in a report in February that, under its supervision, Areva was examining all documents related to the manufacturing of nuclear reactors for irregularities from its wholly-owned subsidiary Creusot Forge.

CGN, Dongfang Electric Corporation Limited, Dongfang Electric (Guangzhou) Heavy Machinery, and Shanghai Electric did not respond to FactWire’s requests for comments on the carbon concentration issue of Taishan’s steam generator.

CGN also did not answer whether the Taishan plant would follow in Flamanville’s steps and replace its reactor pressure vessel upper heads.